France

fr

Français

Caractéristiques techniques

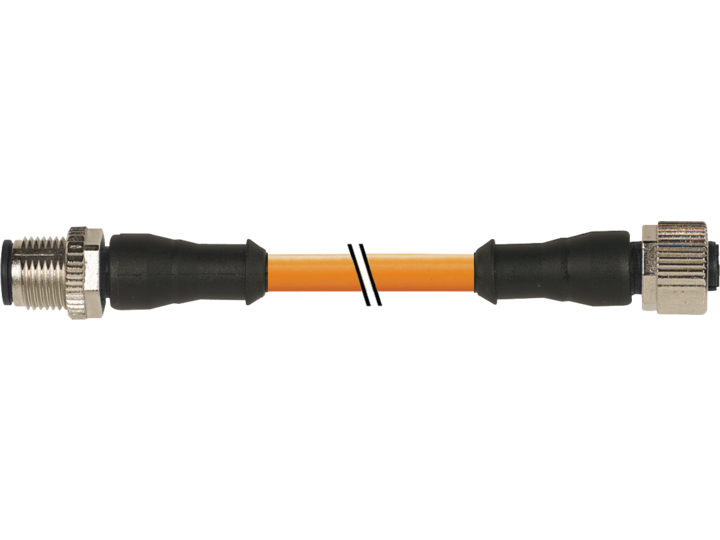

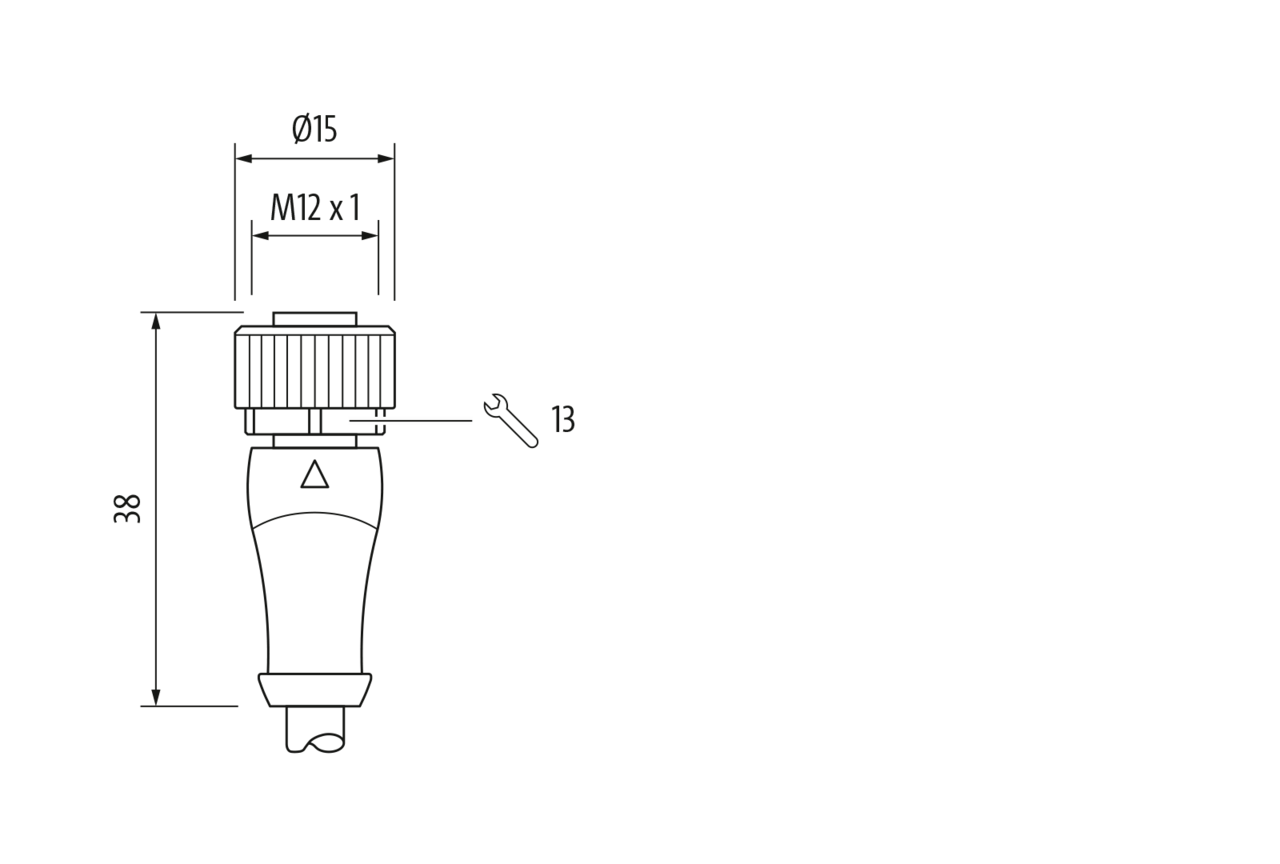

- Head A: Connection

- M12

- Head A: Angle cable outlet

- 0°

- Head A: Gender

- Male

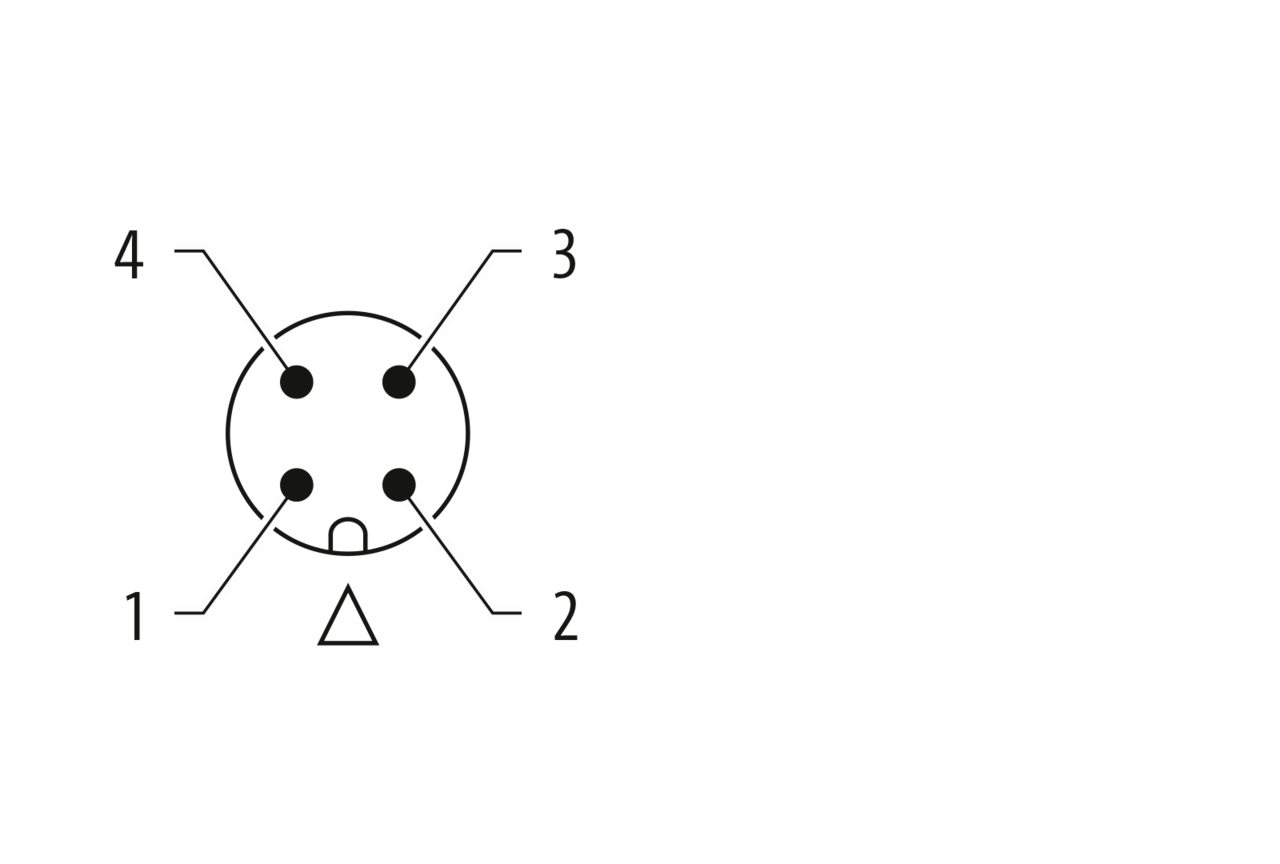

- Head A: Coding

- A

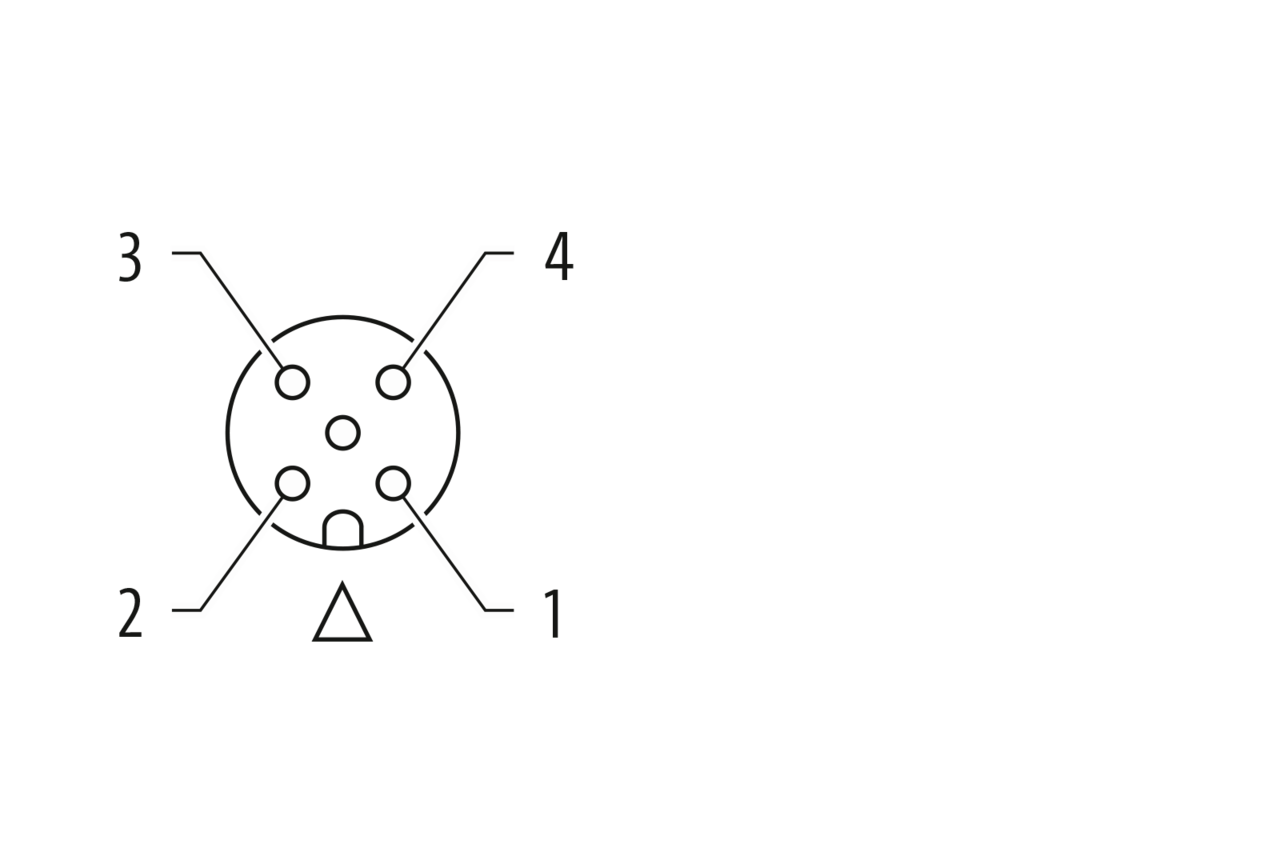

- Head A: No. of poles

- 4

- Head A: LED

- No

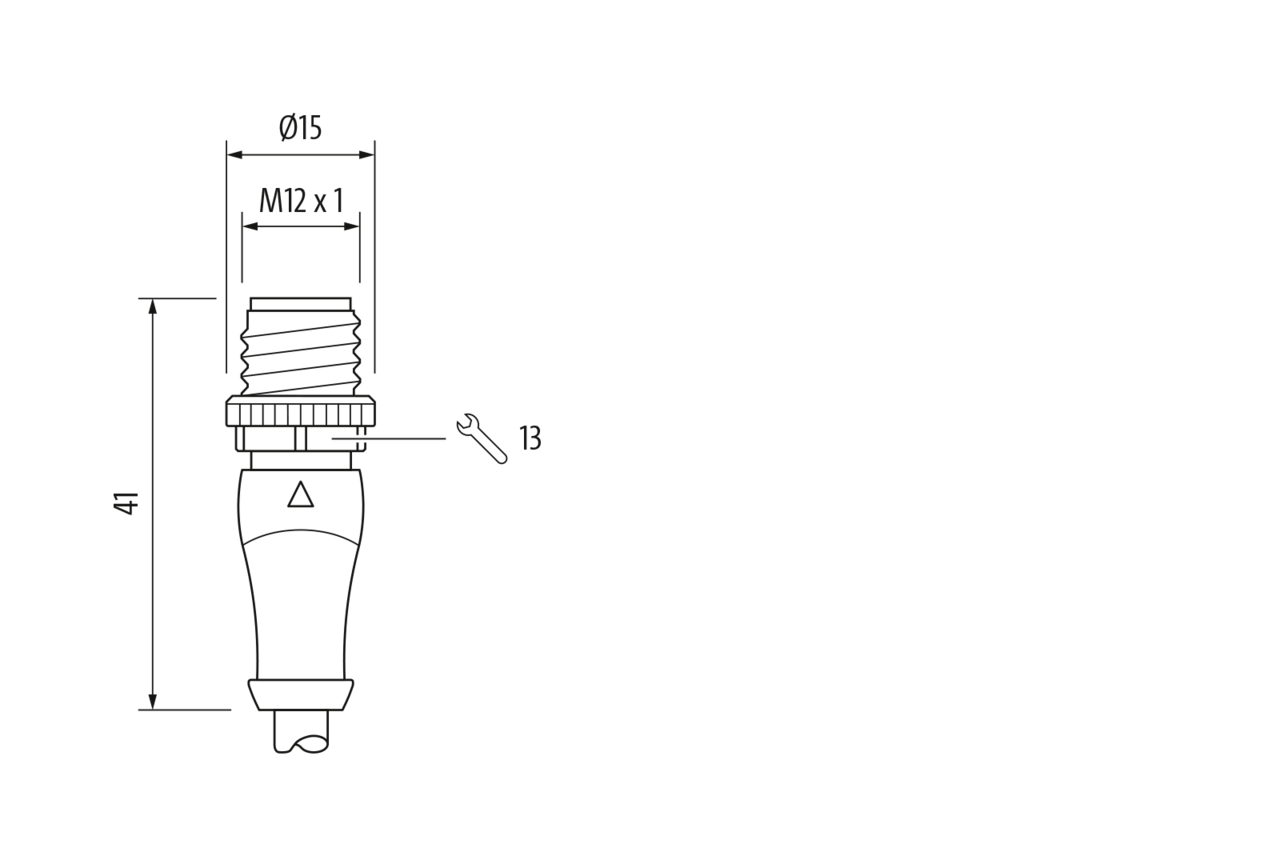

- Head A: Width across flats

- AF13

- Head A: Tightening torque

- 0,6 Nm

- Head A: Knurled nut material

- Zinc-pressure die casting, Ni plated, surface Safe-Cover silvergray matt

- Head A: Body color

- Black

- Labeling sleeve side A

- Yes

- Head B: Connection

- M12

- Head B: Angle cable outlet

- 0°

- Head B: Gender

- Female

- Head B: Coding

- A

- Head B: No. of poles

- 4

- Head B: LED

- No

- Head B: Width across flats

- AF13

- Head B: Tightening torque

- 0,6 Nm

- Head B: Knurled nut material

- Zinc-pressure die casting, Ni plated, surface Safe-Cover silvergray matt

- Head B: Body color

- Black

- Head B: Gasket material

- FKM

- Labeling sleeve side B

- Yes

- Cable length

- 60 cm

- Length tolerance

- + 5 cm

- Shielded

- No

- Conductor structure

- 42 × 0,1 mm

- AWG

- 22

- External sheath: Material

- PUR

- External sheath: Color

- Orange

- Cable diameter

- 4,7 mm ± 5%

- Wire cross section

- 0,34 mm²

Cable

- Cable: Temperature range (mobile)

- - 25 ...+ 80 °C

- Cable: Temperature range (fixed)

- - 40 ...+ 80 °C

- Operating voltage (only UL listed)

- 30 V AC/DC

- Shielded

- No

- Bending radius (fixed)

- 23,5 mm

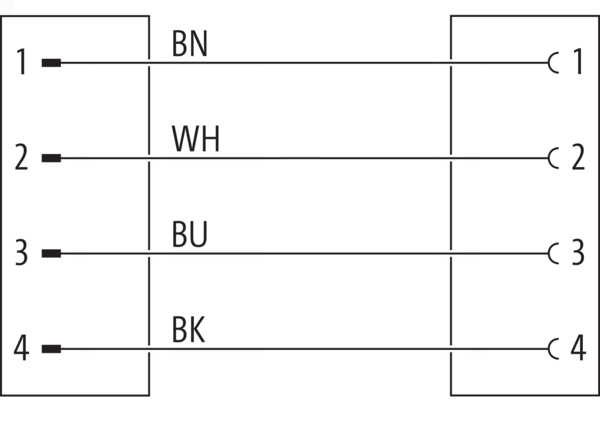

- Number of wires

- 4

- Number and diameter of wires

- 4x0,34

- Length tolerance

- + 5 cm

- Cable length

- 60 cm

- Acceleration (C-track)

- max. 5 m/s²

- AWG

- 22

- Bending radius (fixed)

- min. 5 × outer diameter

- Torsion speed

- max. 35 cycles/min

- Bending radius (mobile)

- min. 10 × outer diameter

- Cable type

- 5

- Cable weight

- approx. 36,3 g/m

- Conductor structure

- 42 × 0,1 mm

- Cable diameter

- 4,7 mm ± 5%

- Conductor: Material

- Copper, bare

- External sheath: Material

- PUR

- Insulation: Material

- PP

- No. of bending cycles (C-track)

- approx. 10000000 Cycles

- Nominal voltage

- 300 V

- No. of torsion cycles

- approx. 1000000 Cycles

- Paired stranding

- No

- Single wire diameter

- 0,1 mm

- Cable: Test voltage

- 2,5 kV

- Torsion stress in °

- ± 360 °/m

- Total stranding

- 4 wires strand

- Travel speed (C-track)

- max. 3,3 m/s

- Traversing path (horizontal)

- max. 5 m

- Wire cross section

- 0,34 mm²

- Wire processing

- No

- Wire diameter incl. isolation

- 1,25 mm ± 5%

- External sheath: Color

- Orange

Données électriques

- Operating voltage

- max. 250 V AC/DC

- Operating voltage (only UL listed)

- 30 V AC/DC

- Nominal voltage

- 300 V

- Contact resistance

- max. 30 mOhm

- Operating current per contact

- max. 4 A

Données mécaniques

- Head A: Degree of protection

- IP65, IP66K, IP67

- Head B: Degree of protection

- IP65, IP66K, IP67

- Bending radius (mobile)

- min. 10 × outer diameter

- Bending radius (fixed)

- min. 5 × outer diameter

- No. of bending cycles (C-track)

- approx. 10000000 Cycles

- Torsion speed

- max. 35 cycles/min

- Torsion stress in °

- ± 360 °/m

- No. of torsion cycles

- approx. 1000000 Cycles

- Acceleration (C-track)

- max. 5 m/s²

- Travel speed (C-track)

- max. 3,3 m/s

Conditions ambiantes

- Temperature range (mobile)

- - 25 ...+ 80 °C

- Temperature range (fixed)

- - 25 ...+ 80 °C

- Cable: Temperature range (fixed)

- - 40 ...+ 80 °C

- Dragchain capable

- Oui

- Head A: Chemical resistance

- No

- Head A: Flame resistance

- HB (UL 94)

- Head A: Oil resistance

- ASTM 1 oil, mineral oils, limited to hydraulic oils

- Head A: Acid and alkali resistant

- No

- Head A: Pollution degree

- 3

- Head B: Flame restistance

- HB (UL 94)

- Head B: Oil resistance

- ASTM 1 oil, mineral oils, limited to hydraulic oils

- Head B: Acid and alkali resistant

- No

- Head B: Pollution degree

- 3

- Cable: Chemical resistance

- Good (DIN EN 60811-404)

- Cable: Flame resistance

- Conform UL 1581 §1090 (H), CSA FT2, IEC 60332-2-2

- Cable: Oil resistance

- Good (DIN EN 60811-404)

- Cable: Silicone-free

- Oui

- Eclass

- 27060311

Téléchargements

Fiche technique

-

Fiche technique – CAM12.A4-11235030

-

Fiche technique – CAM12.A4-11235030

Certifications / Approbations

EPLAN

-

Lien vers le Data Portal