Product portfolio

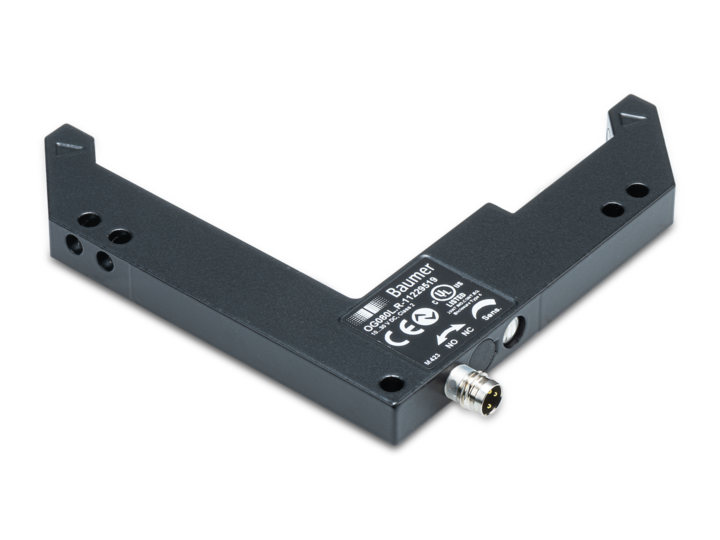

Fork sensors

Angle sensors

Your benefits

- Quick and easy setup

- Transmitter and receiver are integrated in one device saving adjustment effort

- Convenient configuration of sensitivity by potentiometer, teach-in or IO-Link

- Reliable object detection even in demanding conditions

- Detecting any object color or surface

- For use in demanding environments or where dust is present thanks to rugged metal housing

- High system efficiency

- The short response time down to 0.036 ms and the high repeat accuracy guarantee maximum reliability in dynamic processes

- Versatile use thanks to different designs

- Different fork widths as well as U and L-shaped designs available for optimum installation

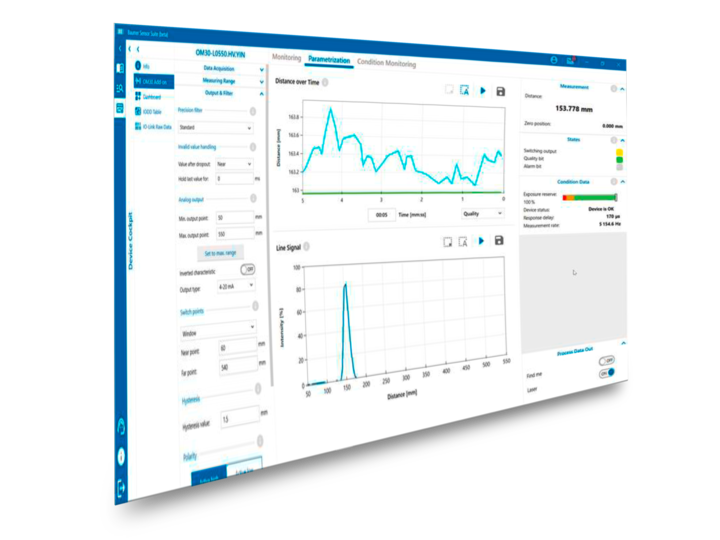

- Flexibility due to IO-Link

- IO-Link permits easy and fast sensor adaptation to the application

- Visualization of any soiling by continuously IO-Link monitored amount of light

Applications

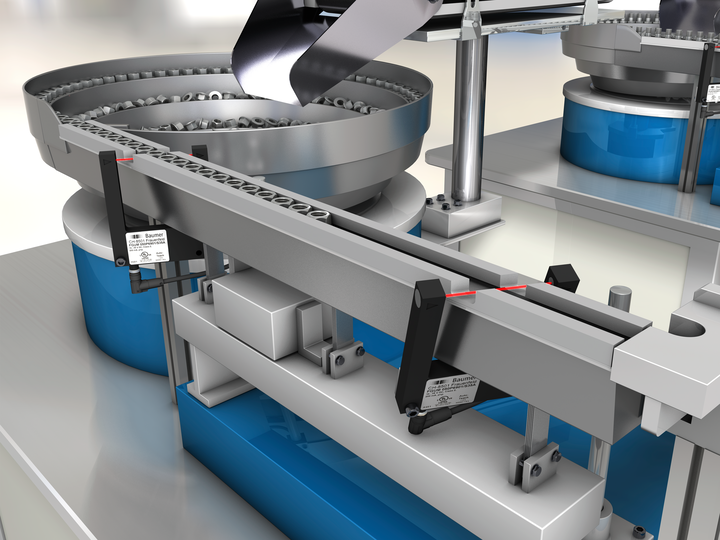

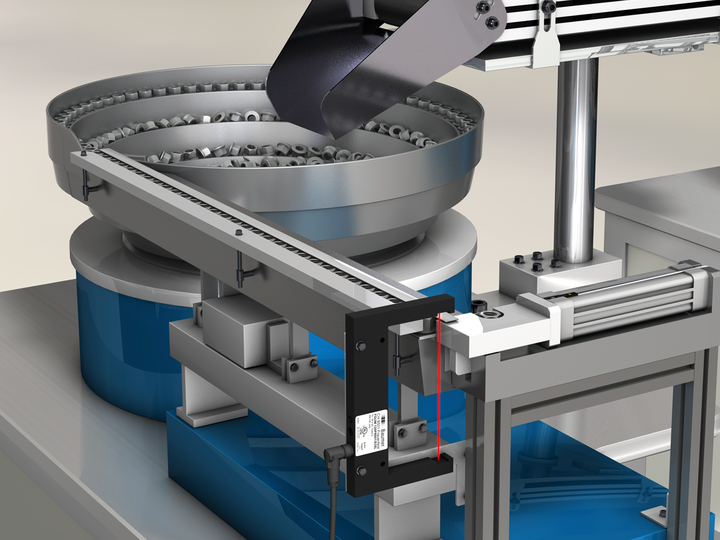

In-track level monitoring

Presence of parts in the nest in feeding technology

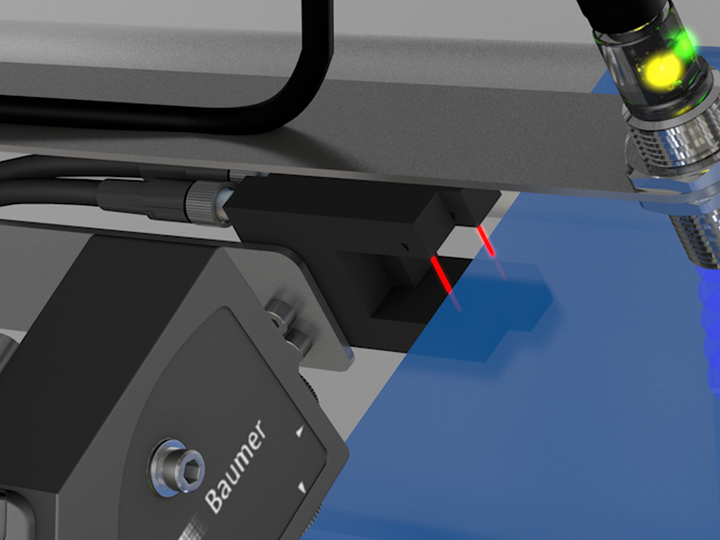

Web edge monitoring in packaging

Technology

Fork and angle sensors as well as through-beam sensors are based on the same basic principle. The scratch-resistant, mineral glass collimator optics used in the fork and angle sensors OGxxxU.R/ OGxxxL.R and OGxxxU.L produces an even and very narrow light beam. This feature gives the sensor its high detection accuracy, which is guaranteed over the entire beam range from all sides.

The largest laser fork sensor can reliably and repeatedly detect a 50 μm object over the entire 170 mm range. The virtually parallel light beam and the small beam angle of the receiver optics allow for installing fork and angle sensors side by side without interaction. They even can be deployed in the manufacturing process of small light barriers.

Configurable sensitivity features two different options – manually using a potentiometer for less sophisticated requirements on sensitivity or configuration by teach-in.

Potentiometer:

Easy sensitivity adjsutment thanks to mechanical 270° potentiometer directly on the fork sensor.

Teach-in: The teach in functionality allows for quick configuration in the field by simply using the teaching button or external cable.