Switzerland

ch

English

Product portfolio

Use cases

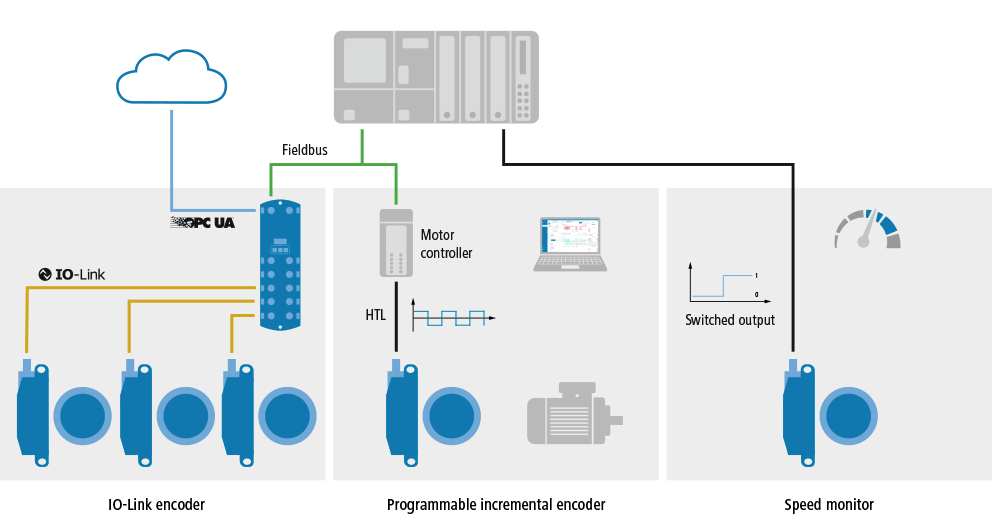

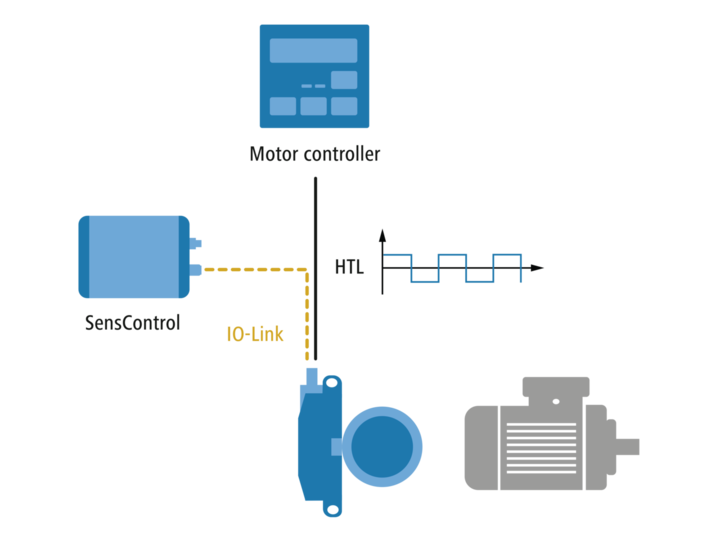

Speed monitoring with cost-efficient connection and parameterization flexibility

EB200E Video

Your benefits

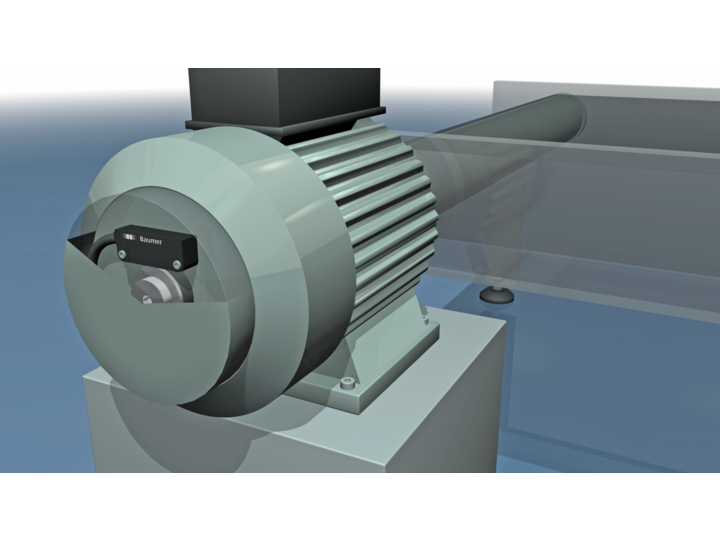

- Compact machine design

- Shallow installation depth of merely 12 mm thanks to radial sensing

- Integration flexibility for shaft diameters up to 48 mm

- Reliable long-term operation even under extreme conditions

- Wear-free non-contact magnetic sensing

- Resistant to dirt

- Resistant to shocks and vibration

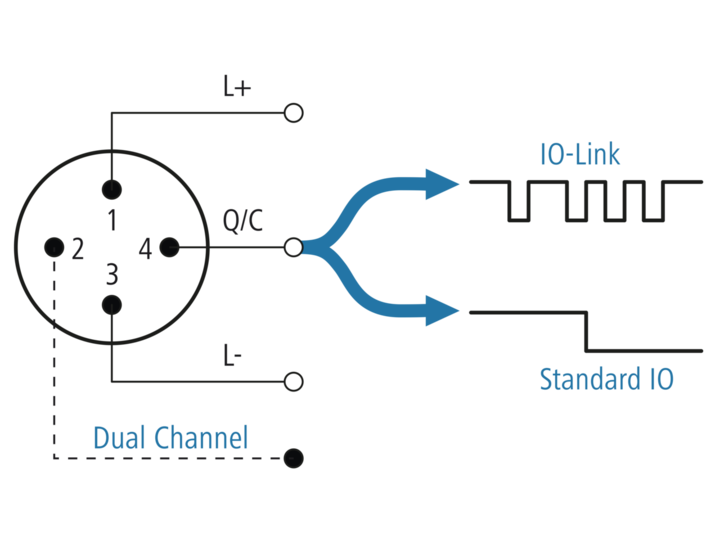

- Cost-effective electrical integration with IO-Link

- No PLC counter modules required

- Use with standard IO-Link cables

- PROFINET or Ethernet/IP via IO-Link master for up to eight encoders

- Breaking new ground in terms of commissioning, service and maintenance

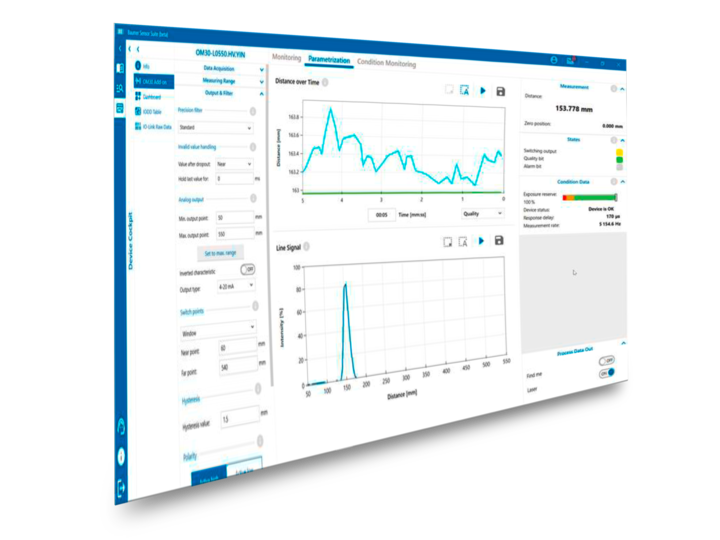

- Easy parameterization with the Baumer Sensor Suite

- Reduced warehousing

- Minimized downtime thanks to completely wear-free design

- Secondary data via IO-Link

- Easy retrofitting of existing installations

- Easy monitoring of existing processes by the parameterizable Speed Monitor without additional components

- For overspeed monitoring at conveyor belts or fans

Applications

Textile machinery

Drives

Intralogistics and AGVs

Wood processing

Hoists

Conveyor belts

Technology

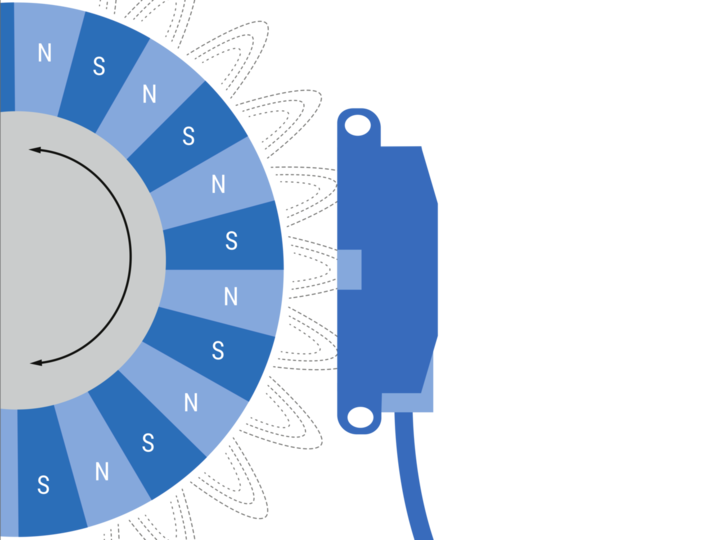

Magnetic sensing allows for large gaps between sensor and material measure (usually magnetic ring or center magnet). This way they can be positioned separately from each other, eliminating the need for precision ball bearings usually deployed with rotary encoders.

In parallel, this allows for high mounting tolerances. This provides more flexibility in design and installation. As there is no need for bearings, there is no conventional wear either. This makes the encoders immune to dust, dirt or textile fibers, immune to shaft currents or bearing loads, and robust against vibration and shock.

Functionality of radial sensing

Permanently high IP protection class

Immune instead of robust

Downloads

Technical and Application Reports / White Paper

-

Technical Report – EB200E