The Baumer conductivity transmitters are designed for media separation and analysis in applications in the food and beverage industry and water treatment. They provide outstanding benefits in terms of accuracy and display options.

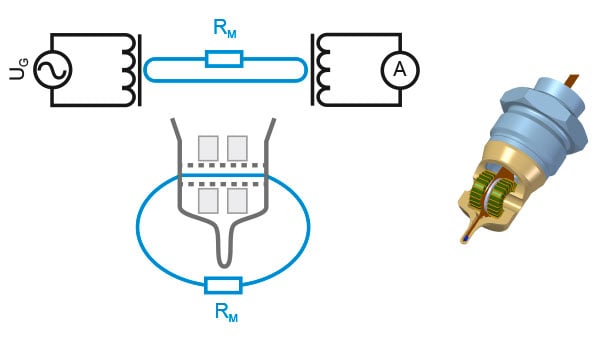

Operating principle of an inductive conductivity sensor Baumer AFI

Differentiation of conductive and inductive technology

The classic set up of conductive conductivity sensors, whose electrodes are in galvanic contact to the medium to be measured, is limited by the point at which high ion concentrations may result in the so-called polarization effect. This can constitute an additional resistance, distorting the measurement result. Similarly, deposits (e.g. sodium hydroxide) can create insulating layers that make conductive conductivity measurement impossible.

For applications with high ion concentrations, such as leaches and acids with conductivity values in the range of 100 mS/cm and when there is a risk of deposits, inductive technology offers the only reliable conductivity measurement and thus reliable control of processes. However, the inductive measurement principle is not suited for measuring very small conductivity values. The smallest measurement range is 500 µS/cm (0.5 mS/cm); in this range precise measurements of around 50 µS/cm can still be carried out.

Design of the inductive conductivity sensor AFI

The sensor element with a seamless PEEK housing contains two ring core coils that act as two virtual transformers arranged in series. The first primary winding is fed by an oscillator in the kilohertz range. The liquid loop that is created by the current measuring passage through the interior of the two ring core coils and the surrounding area connects the secondary side of the first transformer to the primary side of the second transformer. This connection can be considered a common winding of both transformers. The secondary winding of the second transformer is connected to a galvanometer. The volume of the liquid resistance RM results in an associated current measurement value. Using a simple calculation rule (Ohm’s law), this value together with the known oscillator voltage UG is transformed into the conductance value GM to be output.

The sensitivity of the galvanometer must be adjusted for different conductance value ranges. The user can do this by setting freely defined measurement ranges that can be selected during operation by activating control inputs.

The inductive measurement principle is not reliant on the movement of liquids in the current measuring passage. Nevertheless, it is recommend to align the channel in the direction of the flow to achieve better cleaning results. The symmetrical design of the channel accommodates both flow directions without the risk of clogging by media components.

A precise and highly responsive Pt100 temperature sensor is integrated into the tip of the sensor element. The temperature of the medium measured by this is available as a measuring signal and is used in addition to the physical temperature compensation of the raw conductivity value.

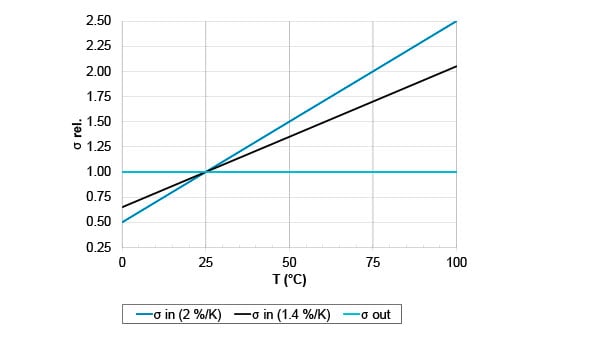

Temperature compensation

The conductivity of a liquid generally depends on the temperature. For many aqueous solutions, it increases at +2%/K. To be able to compare measurements, measuring devices refer the directly determined conductivity back to a reference temperature. This is usually defined as 25 °C. In addition to this definition, the AFI also allows the input of a temperature coefficient in %/K. This must be set to 0%/K if temperature compensation is to be dispensed with. Non-linear temperature coefficients can be specified with an additional quadratic element.