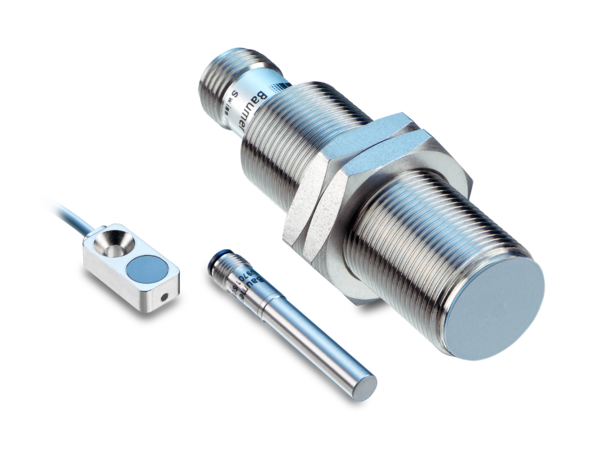

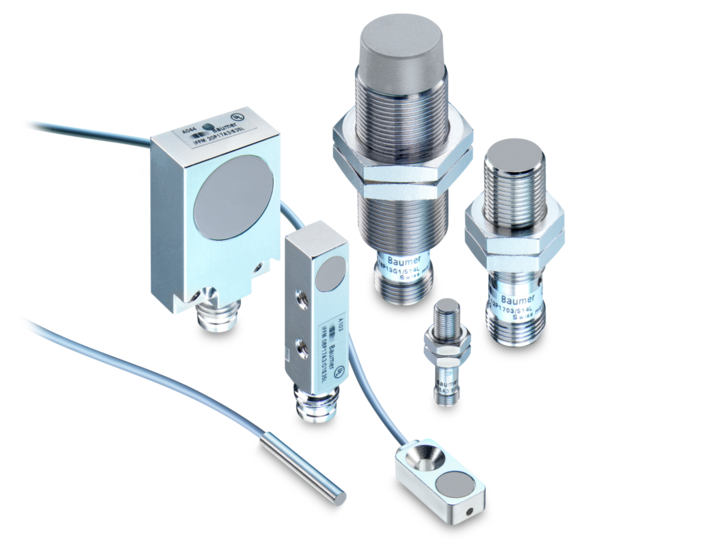

Baumer inductive proximity switches are non-contact electronic sensors. Inductive sensors will recognize any conducting metal target.

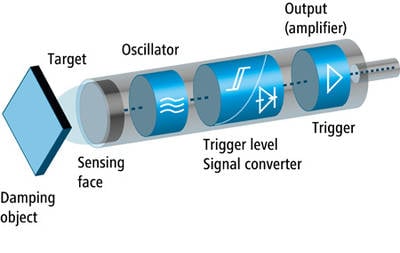

The oscillator creates a high frequency electromagnetic field, which radiates from the sensing face of the switch. When a conductive metal object enters this electromagnetic field, eddy currents are induced within the metal, causing a change in the amplitude of the oscillations. The result is a voltage change at the output of the oscillator, which causes the trigger to change state and alter the output state.

Visit our inductive proximity switches portfolio

Sensing characteristics of inductive proximity switches

Sensing distance

The international standard EN 60947-5-2 defines the sensing distance as follows: the sensing distance is the distance at which a standard target moving toward the sensing face of a proximity switch causes a signal change.

Standard target

The standard target is defined as a square plate, 1 mm thick, made of Fe 360 (mild steel). The length of its side is defined as the larger of either the sensing face diameter or three times Sn (nominal sensing distance).

Nominal sensing distance Sn

Nominal sensing distance Sn is a type classification parameter and does not take into account tolerances during machining or changes due to external conditions such as voltage or temperature.

Effective sensing distance Sr

Effective sensing distance of an individual proximity switch which is measured at a defined temperature, voltage and installation conditions. For inductive proximity switches it must be between 90% and 110% of the nominal sensing distance at 23 ±5 °C.

Usable sensing distance Su

Sensing distance of an individual proximity switch measured over the temperature range and at a supply voltage of 90% and 110% of the rated value. For inductive proximity switches it must be between 90% and 110% of the effective sensing distance.

Assured sensing distance Sa

Distance from the sensing face at which the operation of the proximity switch is ensured under defined conditions. For inductive proximity switches the assured sensing distance is between 0% and 81% of the nominal switching distance.

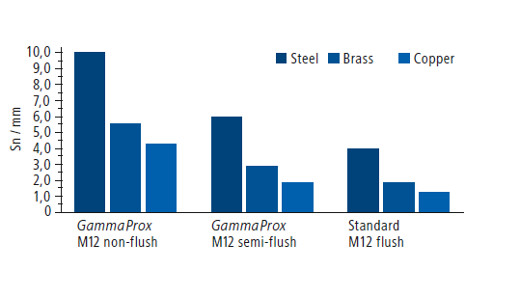

Especially large sensing distances– GammaProx

The sensing distances of the inductive GammaProx family are up to five times greater than the CENELEC standard value. This enables equally safe and reliable detection of steel and non-ferrous metals. Thanks to the increased sensing distance, it is possible to select generally greater distances to the moved objects, which permits greater installation tolerances, prevents damage, and increases plant reliability.

Due to the increased switching distance, GammaProx sensors react more sensitively to the surrounding material. For this reason, front-flush installation is not possible in all materials. The exact installation conditions and correction factors are specified in the data sheets.

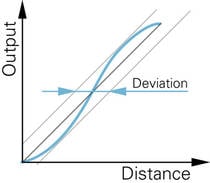

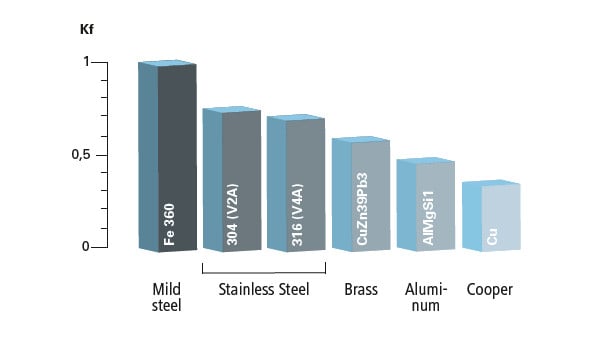

Correction factor Cf

If metallic materials other than Kf those of the standard measuring plate (Fe 360) are used for damping, the specified switching distances must be multiplied by the material correction factor specified in the data sheet. These results should be considered as guidelines. If no correction factors are specified in the data sheet, the standard values specified in this table can be used. Geometries deviating from the standard measuring plate also have an influence on the switching distance.

When sensing aluminum foil or non-metallic materials coated with a thin layer of aluminum or copper, the sensing distance achieved may be close to the value of mild steel. Actual Sn depends on the thickness of the layer as well as the alloy composition.

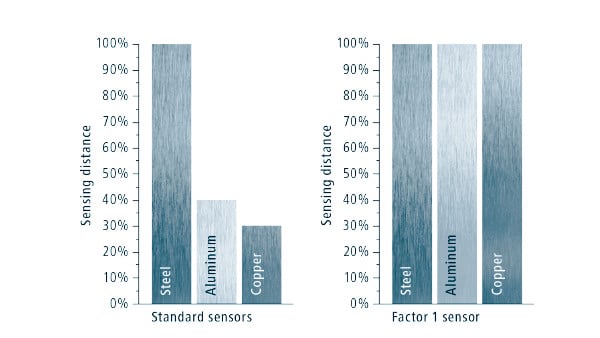

Factor 1

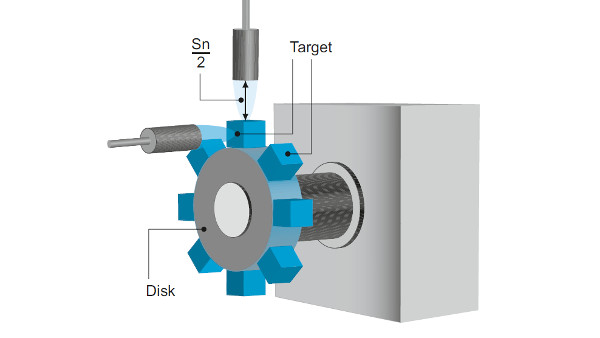

Standard sensors face up to 70% reduction of the sensing distance towards non-ferromagnetic metals. Factor 1 sensors integrate a micro-controller for compensation. As a result, factor 1 sensors do not have the drawback of material-dependent reduction of the sensing distance. They feature negligible temperature drift and also stand out by high switching speed which makes them ideal for measurements on aluminum, nonferrous metals and for rotation speed acquired towards gear wheels or perforated discs.

The uniform distance offers outstanding flexibility in system conception and sensor installation. However, the benefits of Baumer sensors go even further: They are the fastest in their class in relation to sensing distance and have exceptional sensing latitude.

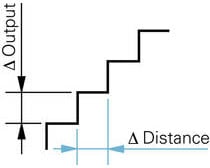

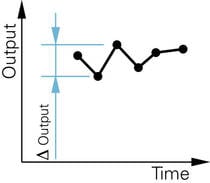

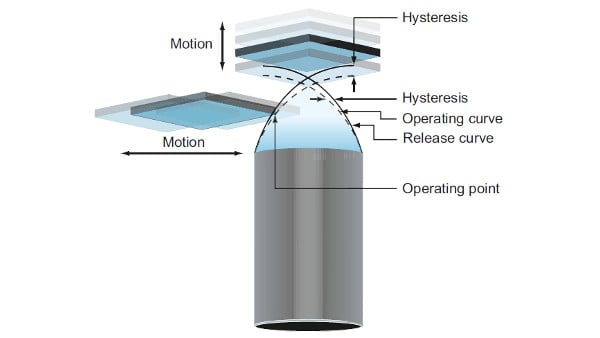

Hysteresis

At approach and removal of the target, there is a difference between operating and release point which is defined as Hysteresis. Hysteresis is designed into a sensor's characteristics to guard against possible incorrect pick-up due to vibration.

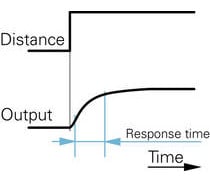

Switching frequency

Meeting EN 60947-5-2 standards, the switching frequency is the highest possible number of switchings per second.