High-performance feature checks

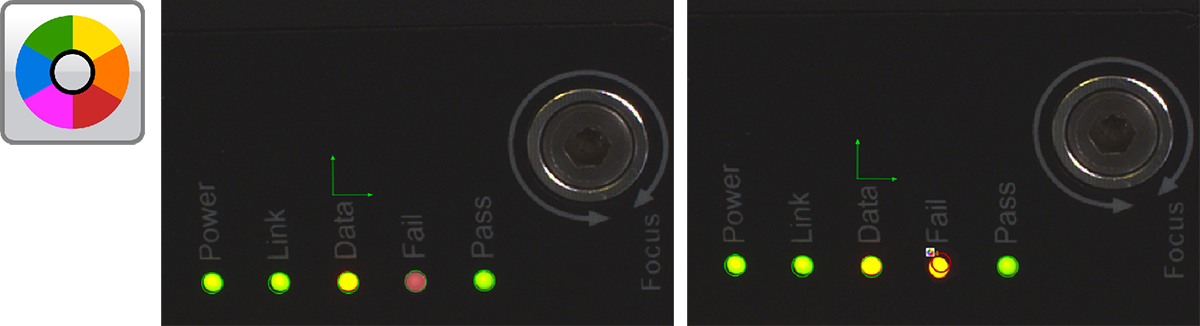

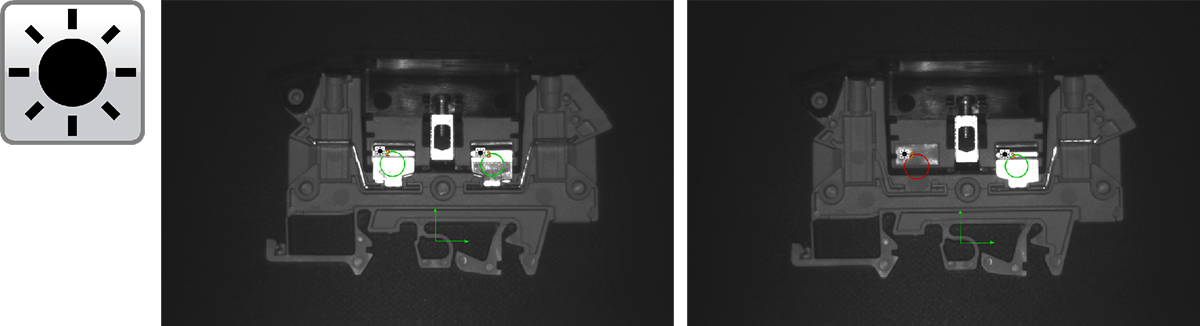

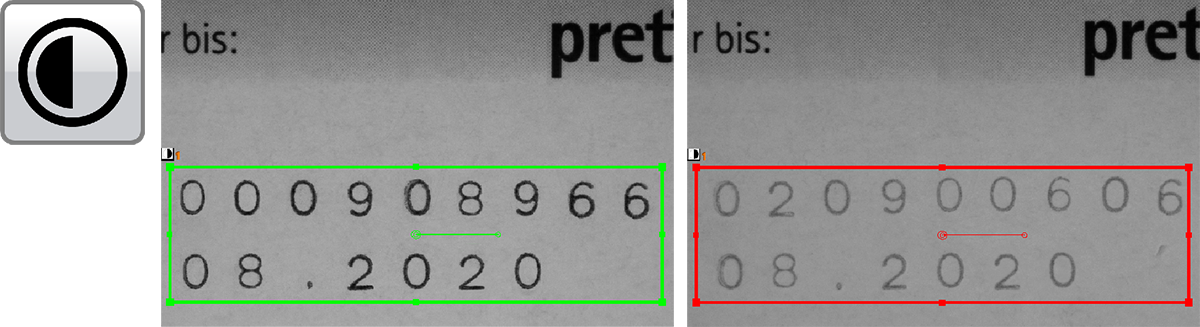

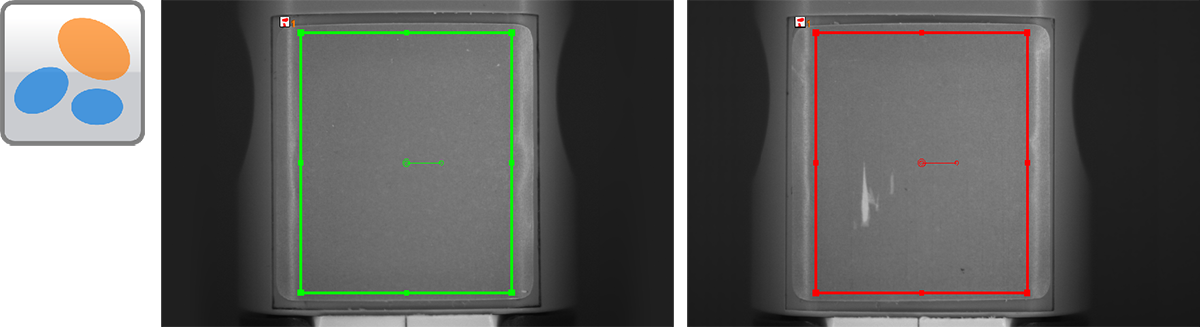

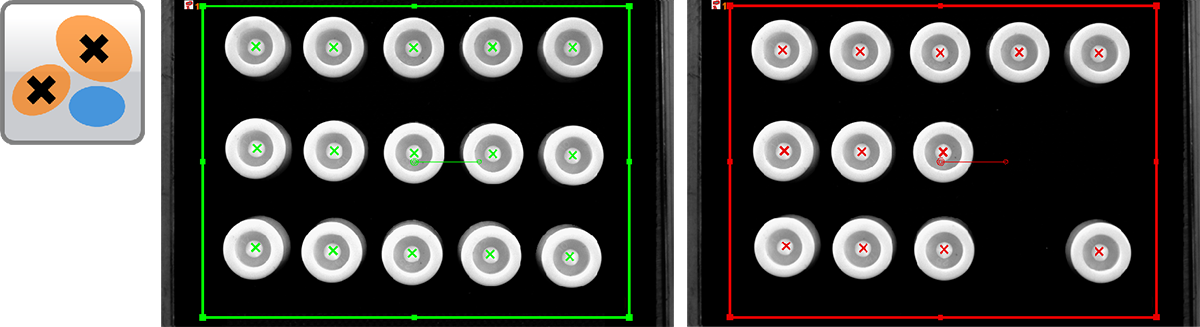

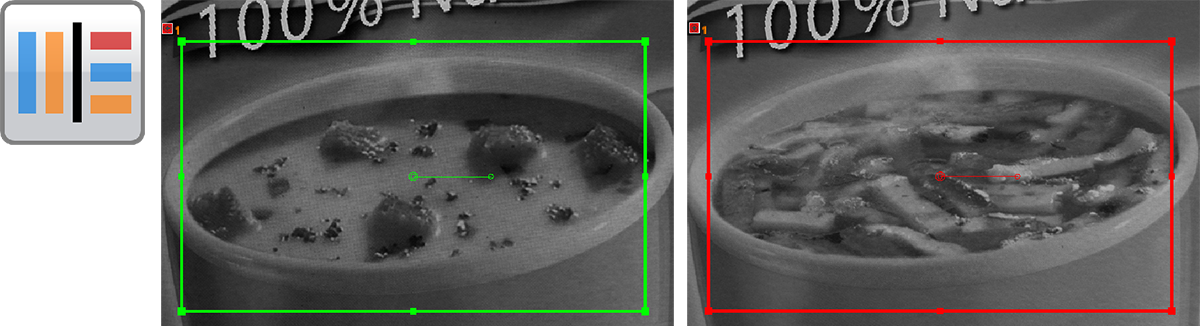

VeriSens vision sensors allow you to accomplish your inspection tasks in no time at all: Recognize errors during ongoing production and react immediately, precisely control robots for pick and place applications, check the best-before date for correctness, or check the correct positioning of assembled items. This extensive range of applications is enabled by the 23 high-performance feature checks that are additionally optimized for easy handling.

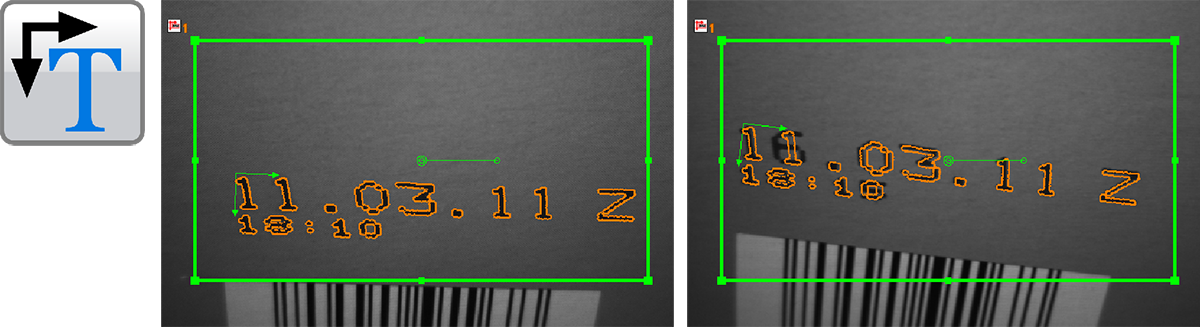

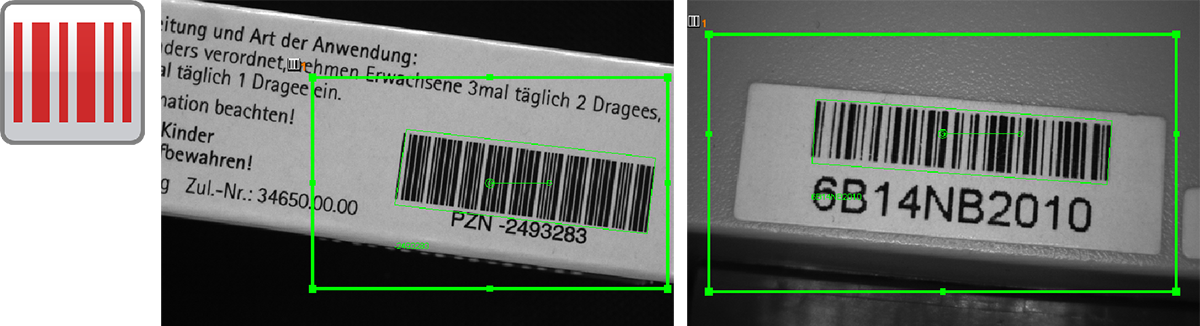

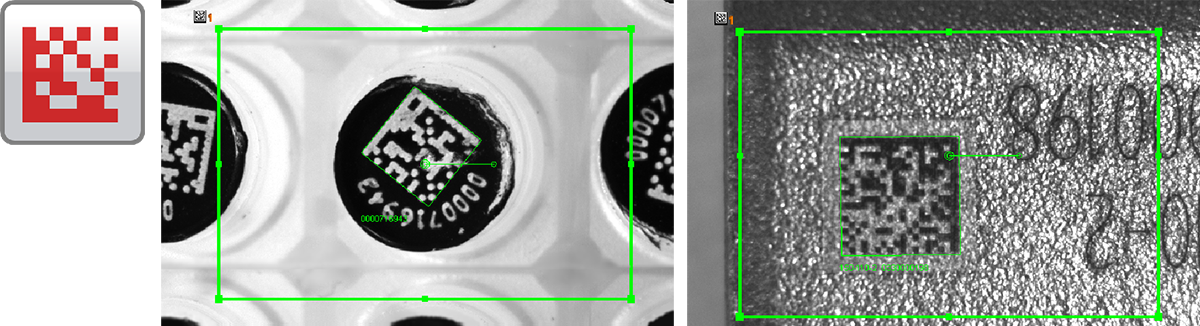

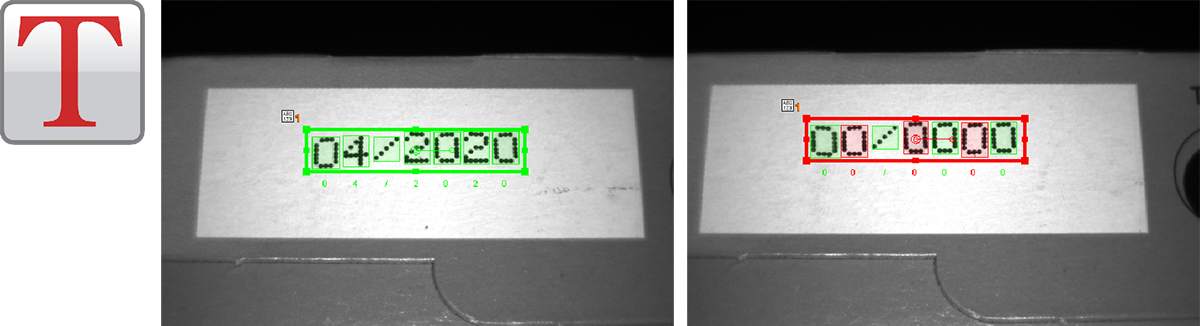

The most extensive range of functions is offered by the 700/800 models of the XF and XC series. You can benefit from up to 22 feature checks, ensuring that you have the optimal image tools available for every application. If, for example, a package should be inspected at the bottler after packaging, there are many features to be checked. Is the content fully present in the package? Is the label attached within specified tolerances? Is the correct inscription on the label in case of production for various resellers? Is the correct bar code (EAN-13/GTIN-13) on the label and readable? Is the printed best-before date correct?

With the VeriSens vision sensors, you can easily accomplish this inspection task with a single image acquisition, as up to 32 feature checks can be combined in an inspection task (job). By the way: A VeriSens vision sensor stores up to 255 jobs. This ensures your flexibility with different products.

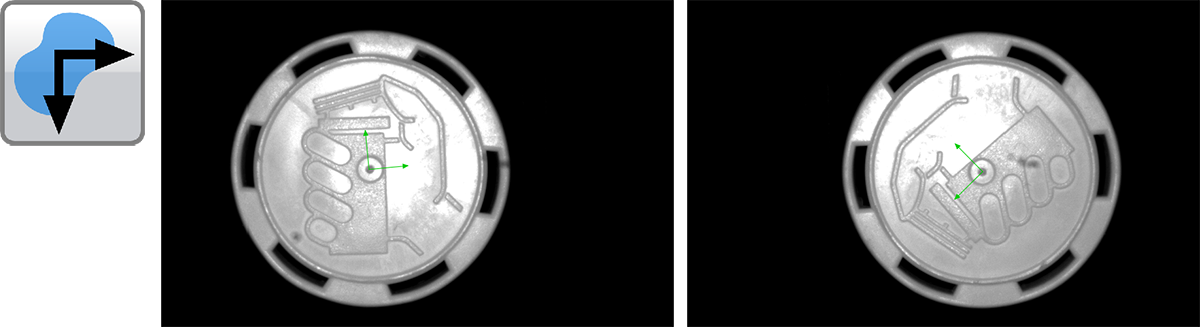

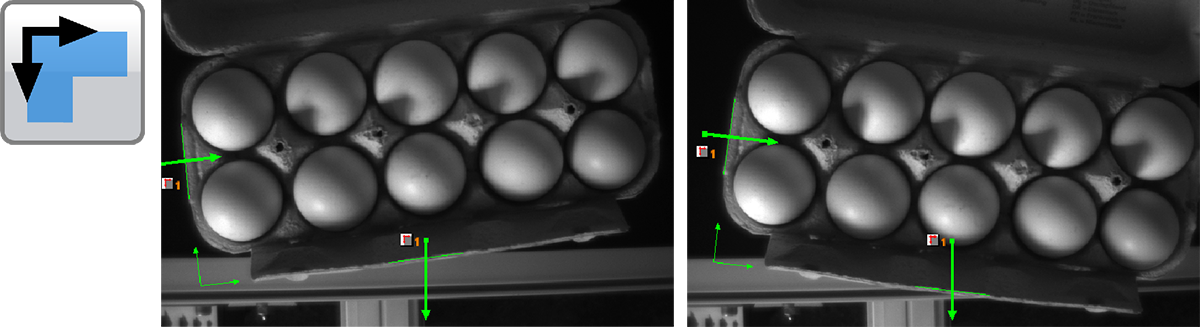

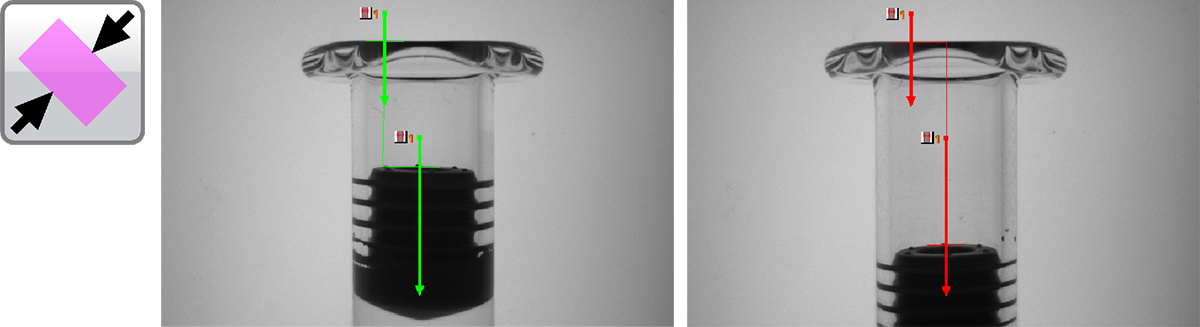

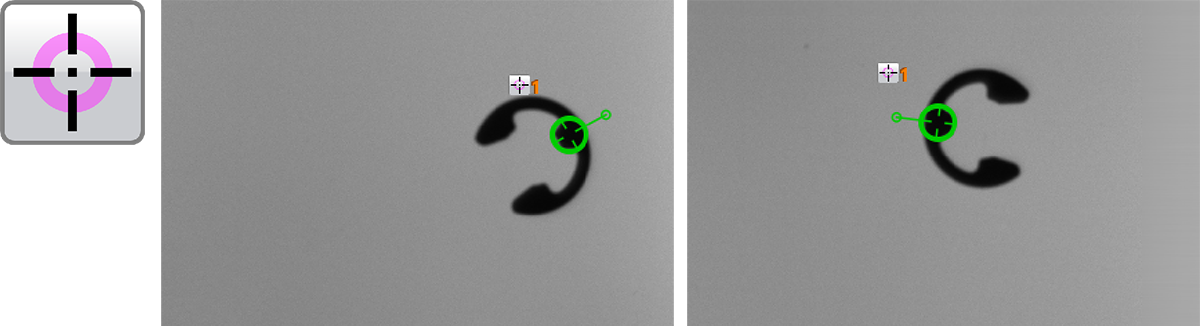

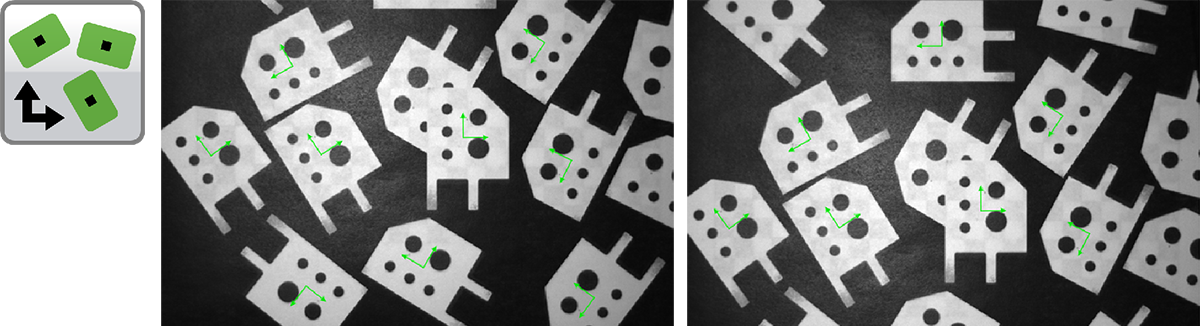

Part location

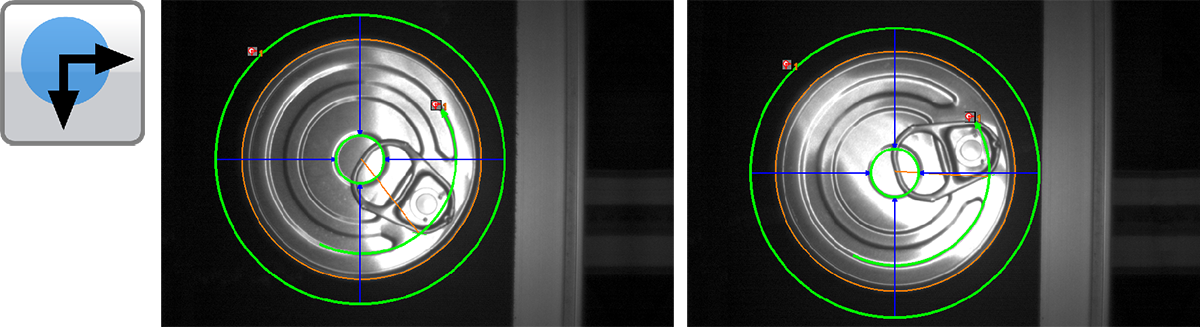

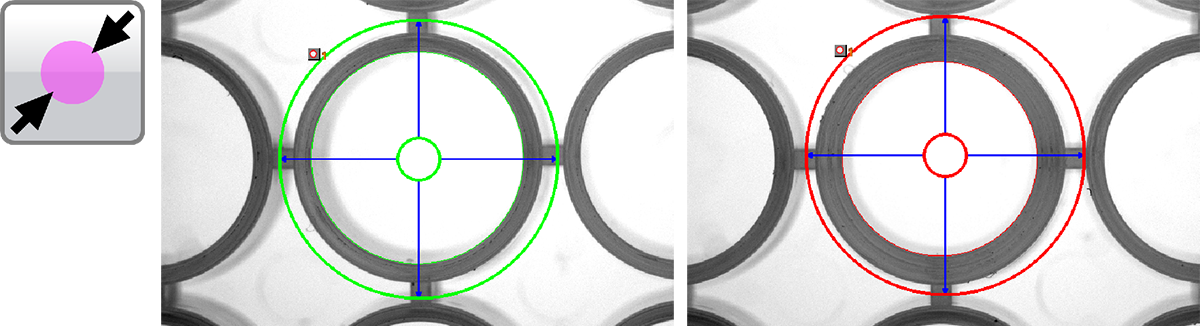

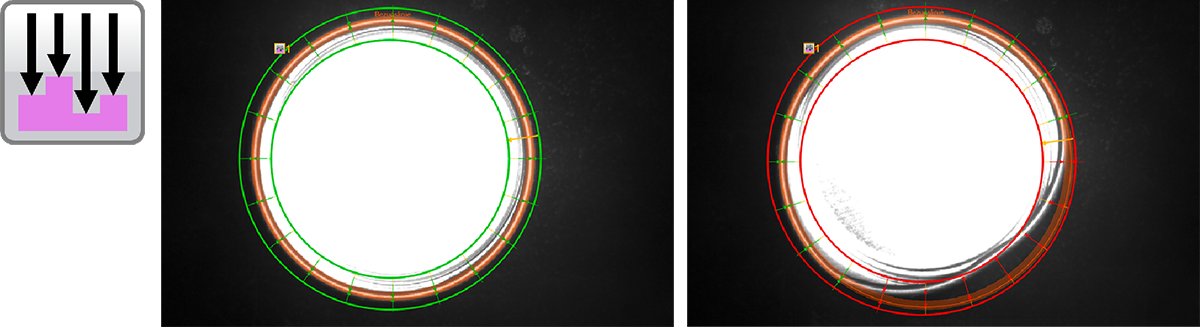

Geometry

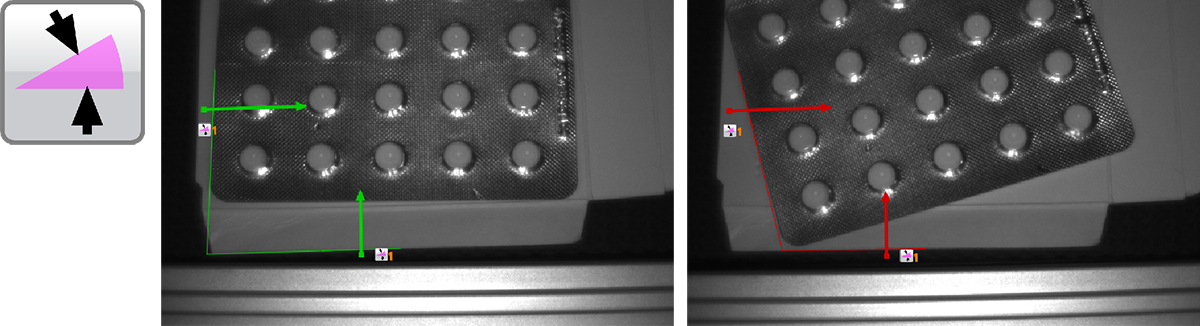

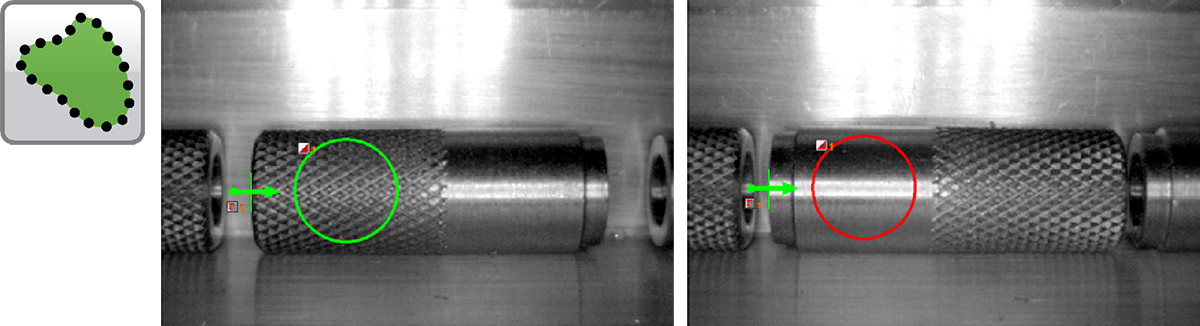

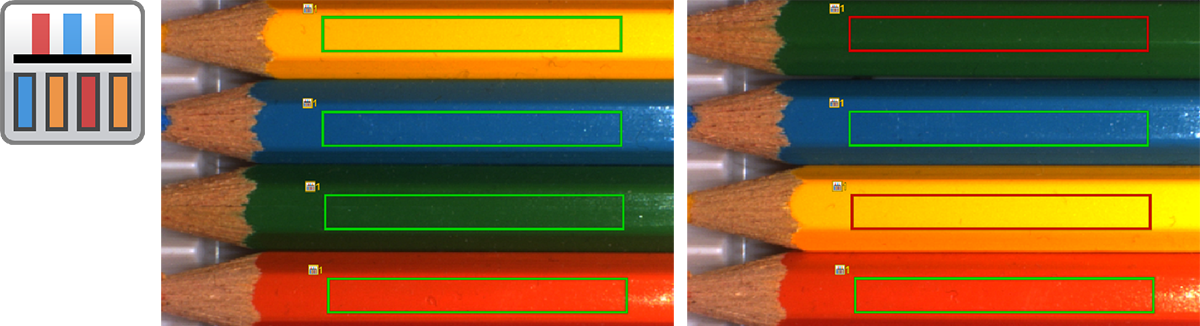

Feature comparison

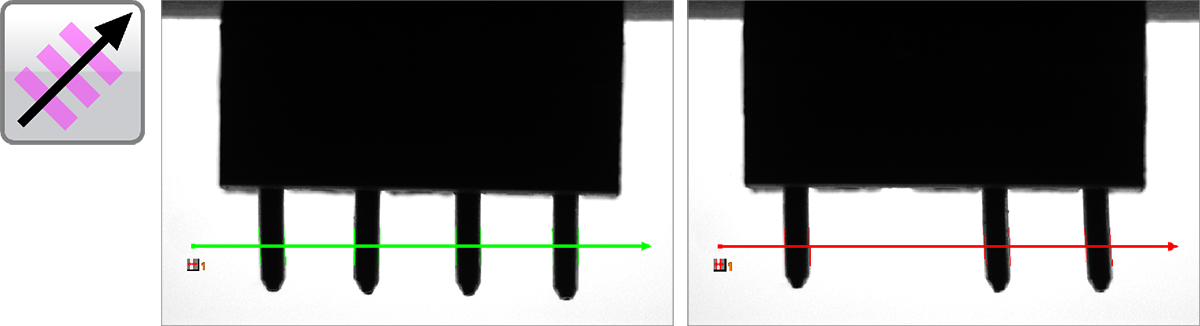

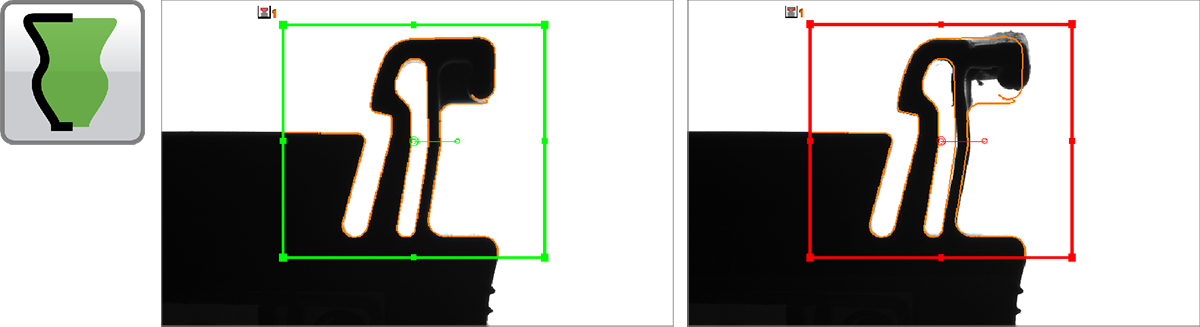

Identification

Product portfolio

Downloads

Brochures / catalogues

-

Brochure – VeriSens vision sensors