Product portfolio

Video “FlexFlow – the calorimetric flow sensor”

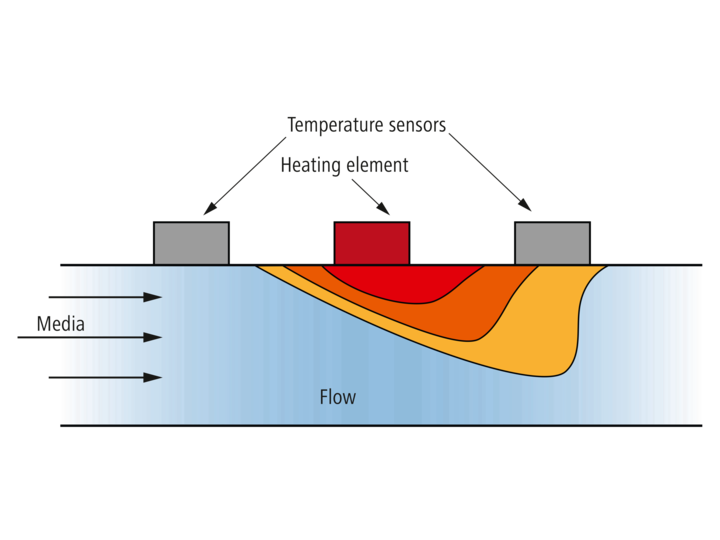

The calorimetric flow sensor for the dairy industry is the solution for many applications from processing to packaging. FlexFlow for monitoring and verifying the cleaning speed in the supply and return lines of your CIP system for optimal cleaning results throughout the system. The calorimetric flow sensor differentiates between no flow and flow by detecting whether heat is removed by the medium or not. By using a symmetrically arranged sensor element, the sensor is independent of the installation position.

Your benefits

- Increased process safety

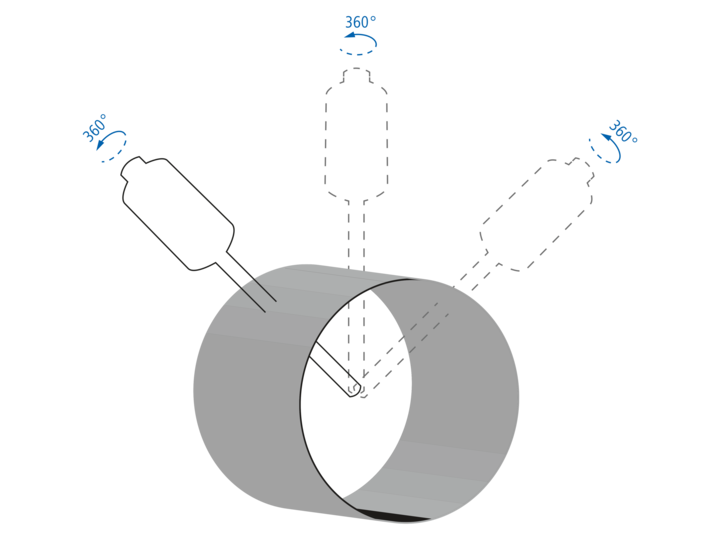

- The symmetrical and centered sensor design allows the sensor to be optimally installed in the process regardless of the installation position and orientation. This ensures precise measurements and process safety.

- Fewer measuring points, less effort

- Combined flow and temperature measurement in a single sensor reduces the number of measuring points and minimizes the effort and cost of installation, service, and warehousing.

- Easy commissioning and efficient fluid management

- The robust stainless steel housing of the FlexFlow flow sensors integrates the entire electronics. This eliminates complicated wiring and the need for control cabinet installation.

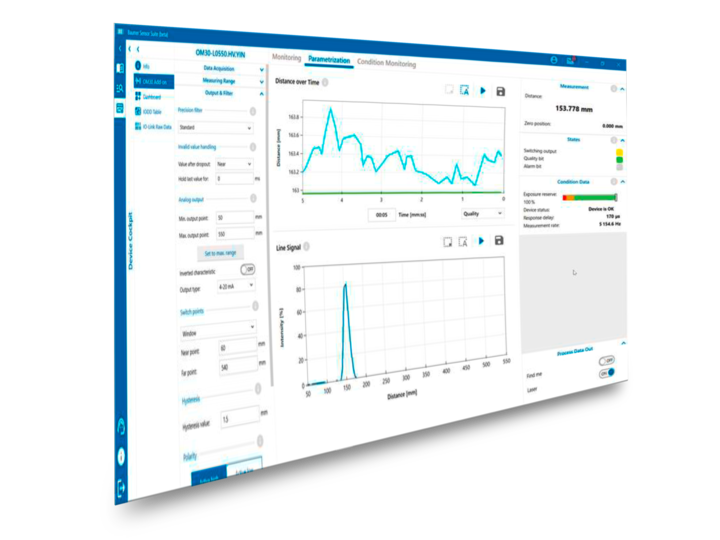

- IO-Link for centralized parameterization

- The IO-Link allows several sensors to be parameterized in parallel. This facilitates the switching point adaptation for various process steps and saves time.

Applications

The sensors are used wherever fluids are monitored and controlled in closed systems.

- Flow control in CIP processes for optimum cleaning results

- Flow measurement of highly pure media

- Dry-run protection for pumps

- Monitoring of cooling circuits

- Spray jet monitoring in cleaning units

- Tool cooling

- Bottle cleaning

- Component cleaning

Technology

Tutorial 1 | Industry variants

Tutorial 2 | Industrial process connections

Tutorial 3 | Correct installation

Tutorial 4 | Volume vs. flow rate measurement

Software

Software

-

Excel – Flowcalculator

Downloads

Brochures / Catalogs

-

Brochure – Efficient flow measurement

-

Flyer – Flow and temperature sensor for hygienic applications FlexFlow PF20H

-

Flyer – Flow and temperature sensor for industrial applications FlexFlow PF20S

-

Catalog – Product Overview – Process Sensors