France

fr

Français

7 mai 2019

Shorter and shorter product life cycles, wider product portfolios, increasing customer demands for individualization – these are the challenges facing manufacturing companies today. If you want to keep up with international competition, you have to increase your efficiency. Particularly in high-wage countries, this is almost the only way to increase your competitiveness. And the ideal way to achieve more efficiency is standardization.

But does that always work? After all, every industry, every machine, every application needs the right technical solution. A good example of this is sensors, whose properties must always be tailored exactly to the specific application purpose. Can specialized individual solutions be avoided at all?

Comprehensive portfolio allows standardization

There is no doubt that standardized components offer tangible advantages: they allow faster product development through the efficient reuse of existing knowhow. Familiarity with the component makes it easier to guarantee quality and to reduce susceptibility to errors. And they reduce operating costs, not least because component storage is simplified and replacement components are more readily available.

But how can the need for more flexible production be combined with standardization, in this case of sensors? A large number of potential applications require sensor manufacturers to offer a suitably wide range of variants, which together result in a complete and optimally coordinated range of products. This allows the customer to easily select the right, optimum solution from an established, comprehensive range.

As a user, you must ask yourself the following questions:

Which sensor principle and which sensor technology are suitable for your particular application?

What are your performance requirements, for example in terms of accuracy or speed of measurement?

Which housing size, design and mounting method do you require?

Which communication interfaces do you use?

Do you prefer a flexibly adjustable or a fixed sensor?

Ideally, the sensor supplier will offer a suitable sensor for each answer to these questions. With a standard range that is broad enough, the user can then choose the optimum solution without having to develop one first. This means that a special solution only has to be developed in situations in which an application is actually too special to be covered by the range. Even with such individual developments, however, the advantage is that they can be derived from the established standards and thus benefit indirectly from them.

Beyond the Standard

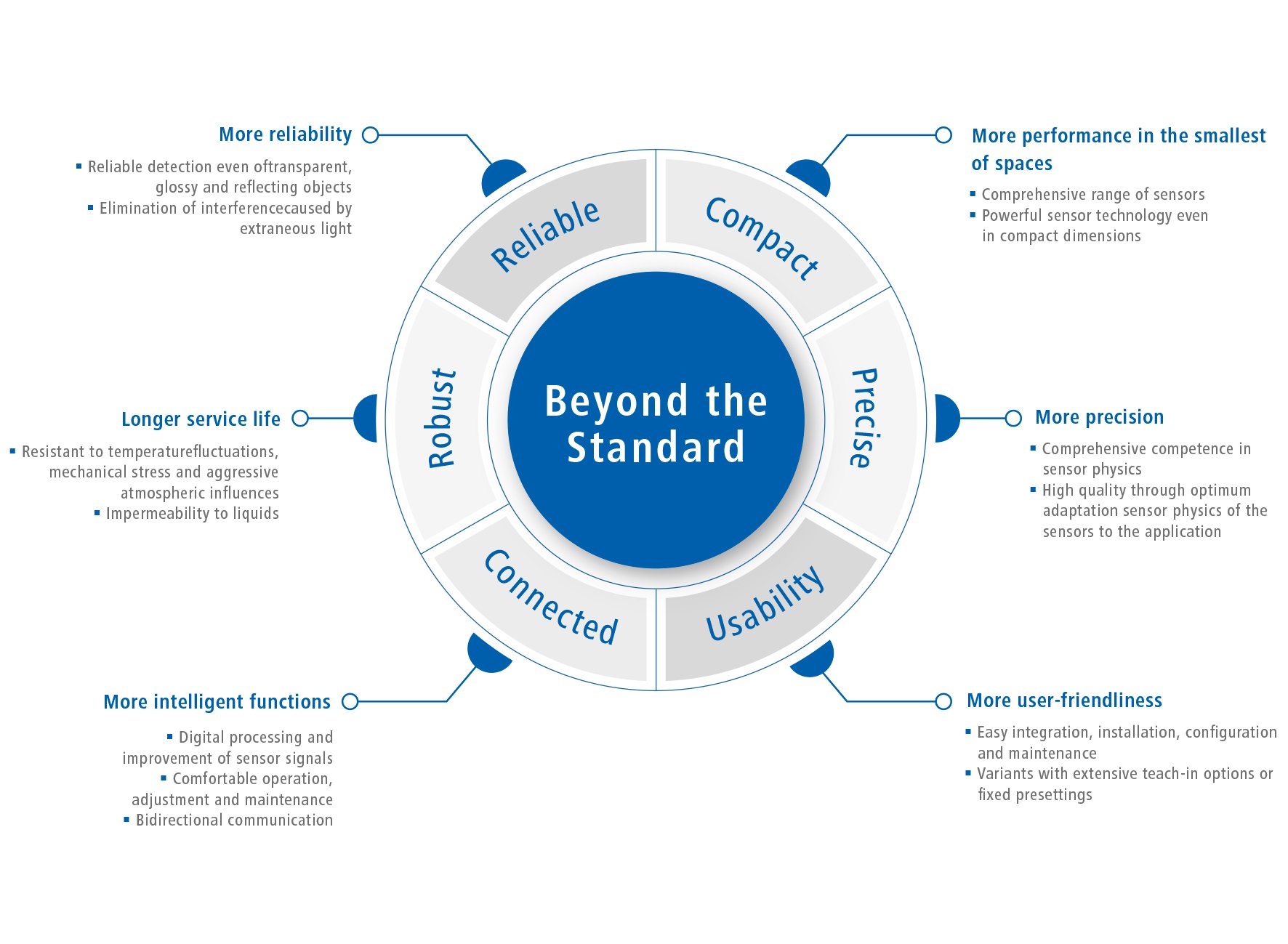

But is "standard" enough for my requirements at all? For us at Baumer:, the following applies: Standard must not mean "average". All of our sensors therefore raise the bar in their class – they are always the standard solution that sets a new standard. With our standardized sensors, users get more than the usual:

- More precision through our comprehensive and profound competence in sensor physics, through the intelligent processing of sensor signals and through high design quality

- More reliability through the elimination of interference

- Longer service life due to long-term high resistance to temperature fluctuations, mechanical stress and aggressive atmospheric influences

- More intelligent functions through intelligent digital information processing for the evaluation and improvement of sensor signals, comfortable and simple operating and adjustment options as well as the use of bidirectional interfaces

- Easy integration, installation, configuration and maintenance for greater ease of use

- More performance in very confined spaces through our ability to fit powerful sensor technology into extremely compact dimensions

This is also why our leitmotif is: “Beyond the Standard”. This refers to standard components that go far beyond the usual. In our theme specials, you can find out more about how our leitmotif is reflected in the individual products.

Télécharger presse

-

Sensors – High-quality standard solution instead of expensive special solutions

-

Picture