United Kingdom

gb

English

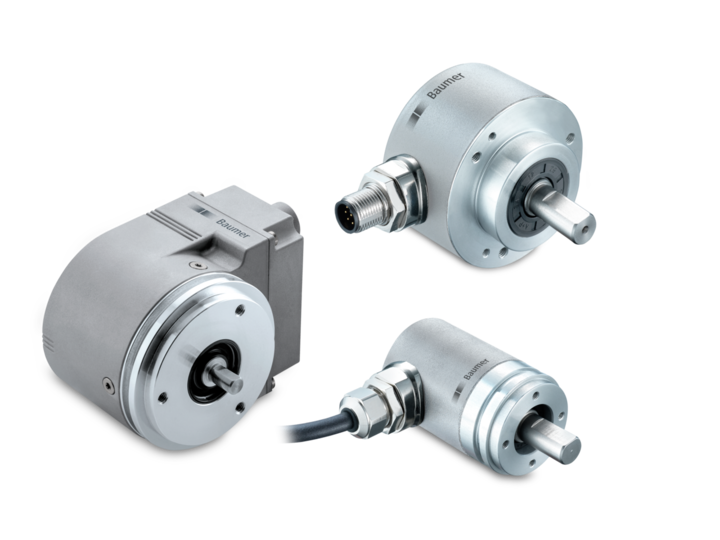

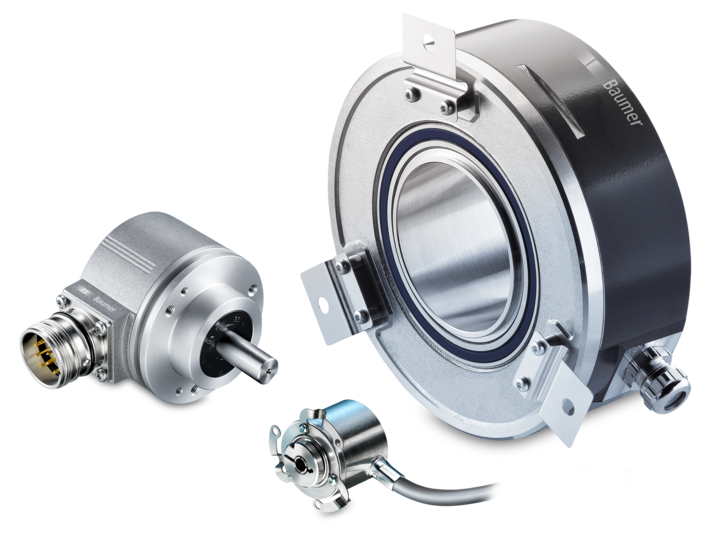

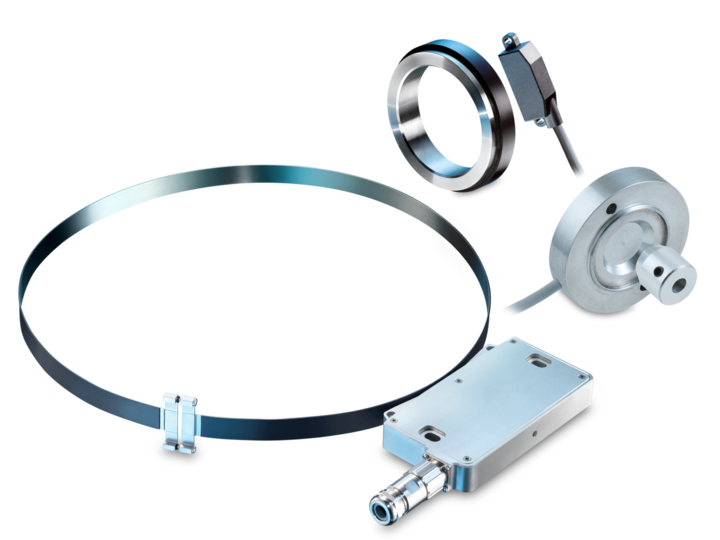

Product portfolio

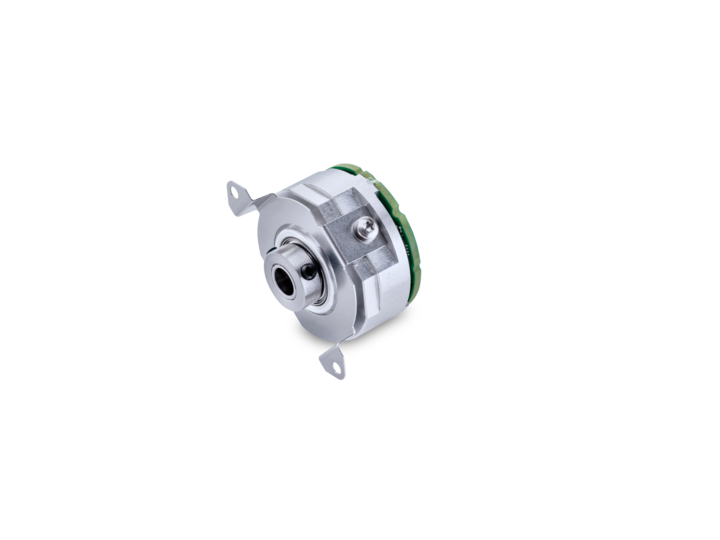

36 mm absolute – BiSS C

EFL360

Your benefits

- Space-saving integration into compact servomotors

- The compact design of the rotary encoders of only Ø36 mm and the low construction depth of 26 mm allow installation even in very confined spaces. This allows simple and space-saving integration into compact servomotors with an edge dimension of 40 mm.

- Accurate and reliable scanning

- The new optical singleturn scanning with Blue LED technology has very parallel light due to the half wavelength. Thus, the distance between the disc and the diaphragm can be increased up to 3 times. The scanning is thus even more robust to shock, vibrations or shifts due to temperature influence.

- Insensitive to interference

- The optical rotary encoders detect and transmit the absolute positional information fully digital. They are therefore substantially more resistant to interference.

- Fast and secure data transmission

- An open, non-proprietary digital interface enables fast, secure and convenient data transmission.

- Long life span

- The scanning with Blue LED technology allows for a low current and optimal adjustment in case of aging, contamination or temperature influence. Especially at higher temperatures up to 115 °C, the lifetime of the LED and thus the encoder is significantly increased.

- Insensitive to contamination

- The three scanning paths, which are over 1 mm wide, are scanned according to the tried and tested Nonius principle and are thus extremely resistant to contamination.

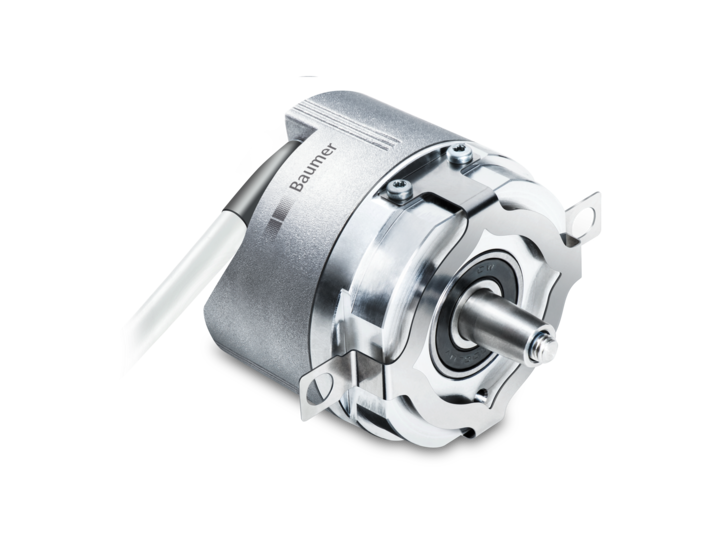

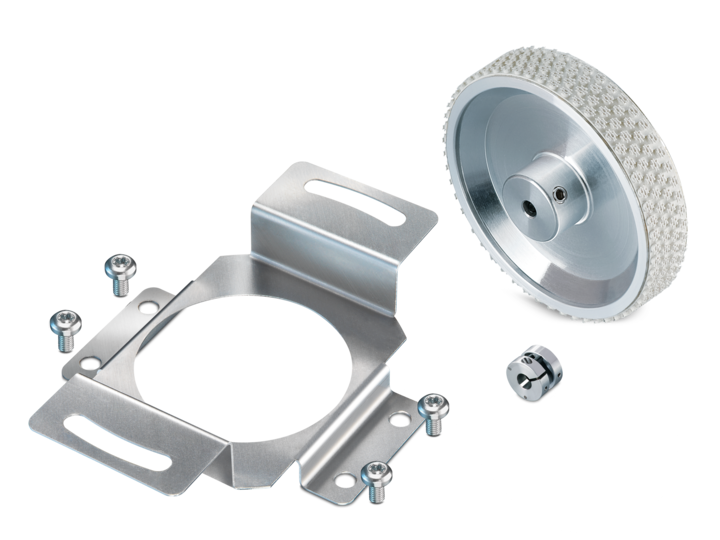

Applications

- Absolute motor feedback encoder – the precise solution for synchronous servo motors

- Absolute motor feedback encoders detect speed, rotation direction and position at electro motors.

- Their main task in the application is commutation as well as speed and position control at synchronous servo motors.

- The number of steps per revolution defines the resolution. The position is acquired once after setup in a referencing cycle and then permanently retained.

- Absolute motor feedback encoders are optimally harmonized for use at synchronous servo motors both in terms of their mechanical and electrical specifications.

Technology

Blue LED for increased compactness, resolution and service life

BiSS C

Downloads

Brochures / Catalogs

-

Brochure – Selection Guide Encoders and angle measurement