Join our expert talk on freely programmable smart cameras for AI and Industry 4.0

Wednesday, May 8 at 2:15 p.m.

Room S403a

Featuring Mike Nagle, Machine Vision Specialist

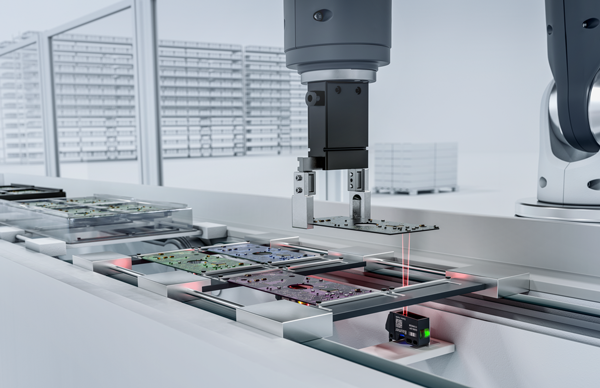

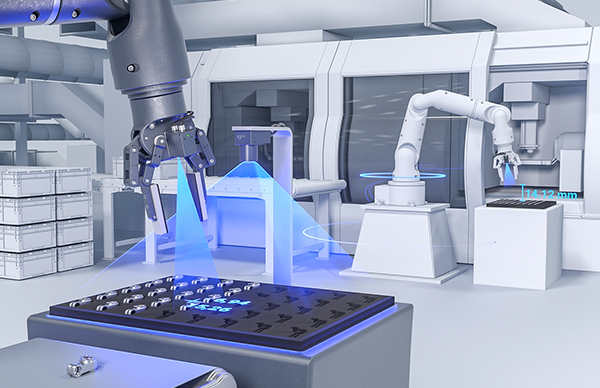

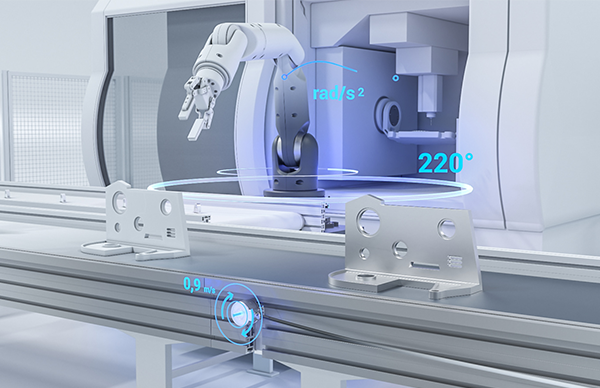

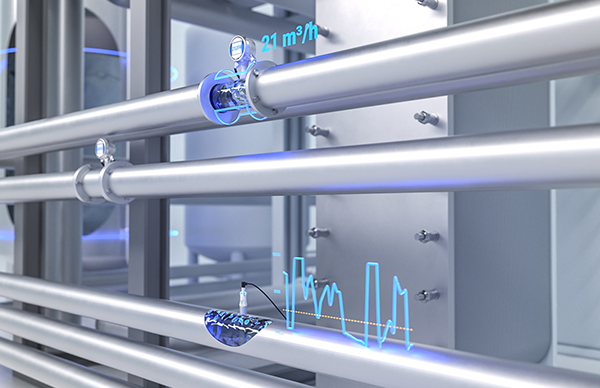

Whether you are trying to find a better way to analyze motions in sports, control stored quantities in your warehouse, or support quick and efficient pick and places processes, AX smart cameras from Baumer with integrated AI core can help you. This revolutionary industrial camera series combines image acquisition and image processing in one unit, saving your company money, space and costs.