Jul 10, 2023

Technical Report: Baumer sensors for safe container handling

The Sensor Solution Toolbox from Baumer ensures precise data and reliable operation in waste disposal: With cable transducers, rotary encoders, inductive sensors and inclination sensors for the "Speed Lifter" waste disposal concept from Villiger AG.

The ever-growing requirements on automation of Mobile Machines and heavy vehicles call for sophisticated and efficient components. This applies in particular to the deployed sensors which are expected to reliably deliver all function and safety-relevant data with utmost precision and at all times- and under whatever outdoor conditions. Here, modern vehicles for waste disposal that automatically lift and empty waste containers are a good example. To ensure efficiency and operational safety without accidents and in compliance with the Machine Directive, the sensors must reliably interact with each other to make sure both operator and safety system are provided with the relevant information at all times.

“Smart City“ is the future, and of course waste disposal is an integer part of it. Vehicles that automatically lift, empty and park waste containers are already a present-day street scenario. Villiger AG in Oberrüti, Switzerland, is recognized as an expert in anticipation of disposal concepts. The product portfolio ranges from above ground and underground containers to lifting and crane systems as well mobile container cleaning systems. With more than 150,000 systems installed in Switzerland and Europe, Villiger is one of the industry leaders with innovative and benchmarking solutions for waste disposal. The “Speed Lifter“ is one example. The specialized “gripper” to lift and hold the container enables all-automated and gentle handling. Quite a number of different sensors support the gripper in safe and quick container handling. For example, cable transducers monitor boom angle and length while absolute encoders acquire boom rotation. Inductive sensors deliver feedback on the outrigger position and inclination sensors monitor vehicle stability. All these measured values are required to define the gripper’s maximum permitted operating range for stability control and to prevent the vehicle from tilting in steep roads or on uneven ground.

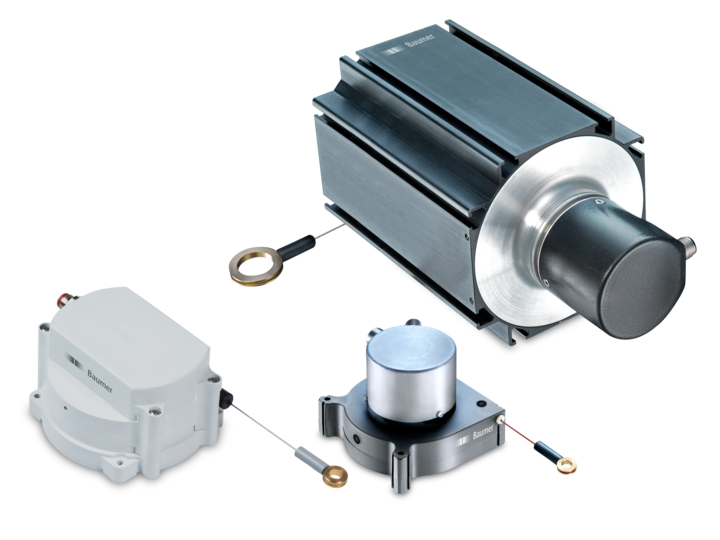

In search for the perfect sensors, the Swiss specialists in waste disposal quickly found what they were looking for in the Baumer portfolio. The sensor expert offers a wide range of robust sensor solutions, from inclination and boom angle sensors to presence checks and position feedback at moving parts on to monitoring load, hydraulic liquid levels and pressure. Numerous sensors especially designed for mobile automation are also available as redundant variant. Optimized to endure strong shocks and vibration and withstanding contamination and temperature fluctuations, the sensors are E1 compliant with C5-M corrosion resistance and protection up to IP69K. Numerous sensors with ISO 13849 – compliant firmware were especially developed for functional safety applications. Compact and extremely robust cable transducer GCA5 reliably acquires the gripper’s boom extension. Especially designed for the requirements of rough mobile outdoor use, it is optionally also available as redundant variant. Thanks to the shallow installation depth of a mere 65 mm, the space-saving cable transducer can be directly installed at gripper boom. The impact-resistant plastic housing, the corrosion-resistant stainless steel cable with abrasion-resistant nylon sheath and non-contact magnetic sensing free from wear make GCA5 the product to choose for reliable and low-maintenance use in waste disposal applications.

Electronics and stainless steel spring mechanism are tightly encapsulated against the cable drum. At the cable inlet, the integrated dirt skimmer acts as additional protection against ingress of moisture and other harmful ambient substances. The maximum measuring range is 4,700 mm, with 0.3 mm resolution and a linearity of ±0.5 % of the measuring range. Rotation under control However, all sensors installed at the Speed Lifter must be durable and precise, for example redundant and magnetic absolute encoder EAM580R detecting boom rotation. The high absolute angular precision of up to 0.15 ° ensures precise positioning.

The E1-compliant design for maximum electromagnetic compatibility with IP67 protection and CX (C5-M) corrosion resistance reflects an encoder design for demanding outdoor conditions. The firmware meets the requirements of ISO 13849, reason why the encoders can be deployed as standard components in functional safety systems up to PLd level. Simplified connectivity by standard automotive connection technology (DEUTSCH, AMP) and the compact design allow for space-saving installation straight in the boom.

CANopen® Communication

The sensors communicate with onboard vehicle control system via CANopen® interface. Absolute encoders of the BMMH58 series monitor the boom rotation angle; inductive switches IR18 are deployed for outrigger positioning. Inclination sensor GNAMG is used for vehicle stability control. Out of these position data the onboard controller defines the maximum operating range which is visualized to the operator in the form of a chart diagram. By doing so, the operator has always an eye on the maximum limits for safe vehicle positioning. The robust sensors have been standing the test of time in state-of-the art vehicles for waste disposal; and at Villiger’s they appreciate the cooperation with Baumer also in other projects. Baumer sensors are also deployed in the mobile CD 300 cleaning system for efficient and cost-optimized cleaning to keep the valuable containers in good condition.

For more information visit

www.baumer.com/mobile-automation

www.villiger.com

Press download

-

Technical Report Baumer sensors for safe container handling