Aug 10, 2023

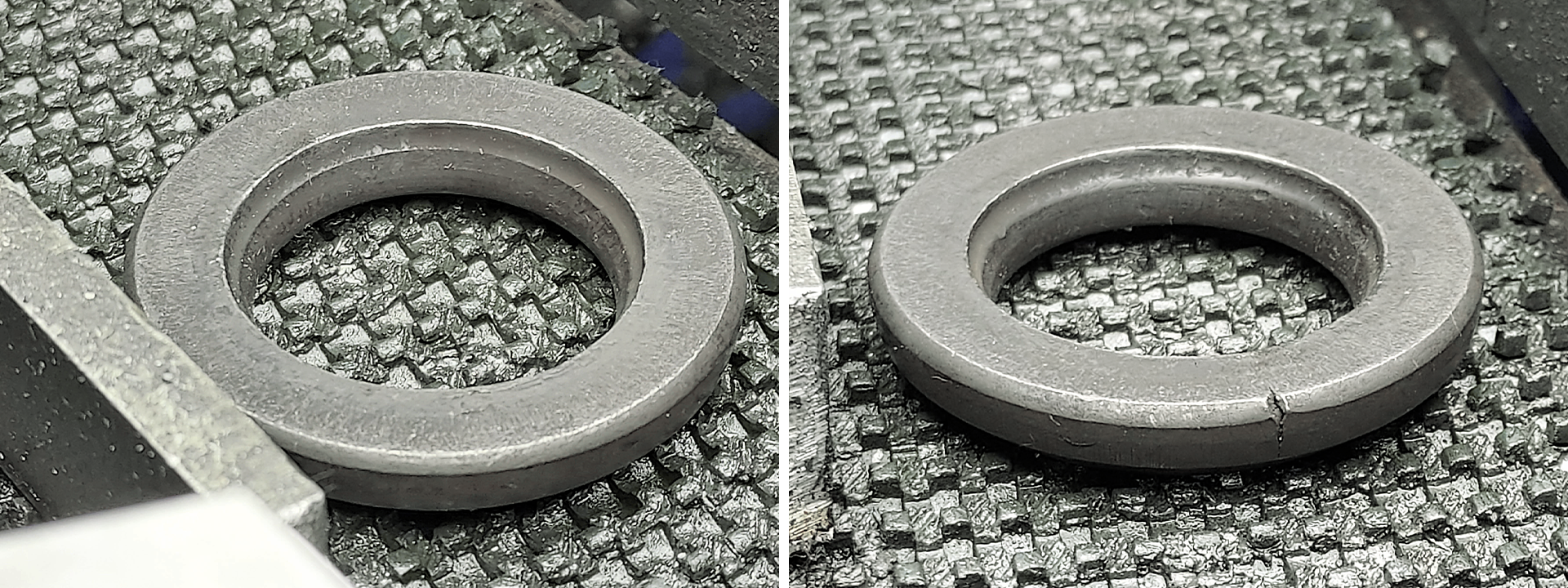

Smart object inspection: Thanks to Deep-Learning algorithms, Baumer AX Smart Cameras will detect macro and micro cracks in mechanical mounting elements

One of the world's leading manufacturers of mechanical fastening equipment and cold-formed parts seeks to improve quality inspection. The solution: Software with Deep-Learning algorithms in combination with the innovative Baumer AX Smart Camera.Intelligently controlling a compact system

Optical quality inspection paired with artificial intelligence

100 percent reliability without operator intervention

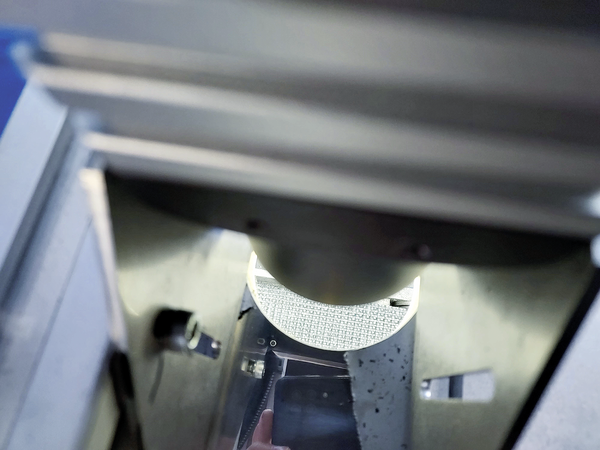

Image processing “at-the-edge“ straight on the freely programmable AX Smart Camera forms a compact system comprising only limited components. Installed straight in the production line it saves time and costs. The Baumer AX Smart Camera with Linux-based operating system simplifies software engineering work with well-known standard libraries and comprehensive performance capacities for both AI and conventional image processing at high frame rates thanks to integrated NVIDIA Jetson technology.

Functionalities, benefits and results at a glance:

Functionalities:

- Superior performance in product quality control

- Automatic in-line recognition of the item

- Integrated rejection system control

- Self-diagnostic functionality

- Data visualization software by beanTech

Benefits:

- Extremely precise real-time control thanks to inline integration of the AX camera

- No additional sensors required

- No interface to MES interface required

- Compact, non-invasive solution

- No retrofit required

- No plant downtime during installation

Results:

- Sustainably improving quality control by inline integration of the Baumer AX Smart Camera

- Assured delivery of compliant parts to customers

- Ensured integrity and functionality of the entire downstream machinery

- Cost reduction by easy, non-invasive integration saving setup time

The beanTech software combined with a Baumer AX Smart Camera fully met the SBE-VARVIT requirements and challenges of quality assurance. “We at SBE-VARVIT, a member to the Vescovini Group, have always believed in innovation. For accessing Artificial Intelligence in our production structure we required the support of experts experienced in the complexity and reality of industry context. beanTech has proved a valid partner in shaping the future we have envisaged for our industry with creativity and tenacity”, says Alessandro Vescovini, CEO SBE-VARVIT.

Guiseppe Parisi, Sales Engineer at beanTech, highlights the role of partnership for successfully completing such a project: “Right from the beginning, the common way with SBE-VARVIT started introducing a quality control system.” From this very beginning, he says, SBE-VARVIT proved to be a competent partner, driven by growing ambition and the need for implementation of AI throughout the entire plant location. “Working with someone having such a clear vision is inspiring and lays the foundation for mutual growth”, Parisi said.

The quality inspection at SBE-VARVIT clearly shows how Baumer creates added customer value by innovative vision solutions such as AX Smart Camera. “This solution impressively shows how modern image processing can contribute towards today’s product quality assurance”, says Peter Felber, Product Manager AX Smart Cameras at Baumer.

The smart combination of conventional image processing and AI algorithms by software specialist beanTech allows for extreme flexibility in quality control without the need for operator intervention. “Here, the AX Smart Camera provides a platform developed for industrial applications enabling “all-in-one” solutions for “at-the-edge” image processing. This substantially simplifies inline integration at production facilities,” explains Peter Felber.