Nov 1, 2023

Smart sensors – grasping the full potential

Fast conception, easy commissioning: Thanks to additional services and tools, users without indepth-knowledge understand and use intuitively the smart functions of Baumer sensors.

The Connected Smart Sensors from Baumer characterize by ultimate precision, miniaturized design and trend-setting functions. Baumer provides helpful digital services to unleash the full potential of smart sensor solutions – for increased plant efficiency and optimized processes in engineering and production. Such digital services improve sensor understanding and usability while in parallel prevent cost-intensive errors in commissioning and installation.

Sensors provide an image of machine reality and this way form the basis for reliable machine control and process optimization. We use to say: In automation, digitalization starts with the sensor. The higher the automation level in 24/7 operation, the higher the demands on sensor precision and reliability. Smart sensors from Baumer allow for ultimate machine performance by powerful measurement technology, innovative design principles and reliable repeatability. They offer parameterization flexibility and durability even in difficult environments, reason why they are ideal for highest automation levels.

Where lies the potential of smart sensors?

What do smart sensors excel with? The measurement physics of such sensors featuring miniaturized microcontrollers is enhanced by integrated functions. Most people associate the term "smart sensor" with IO-Link and secondary data for machine monitoring. To Baumer, however, important features like these are just the beginning. With smart sensors integrating freely accessible additional digital services, sensor expert Baumer offers users maximum ease of operation. Engineers should hurry and exploit the full potential of smart sensors.

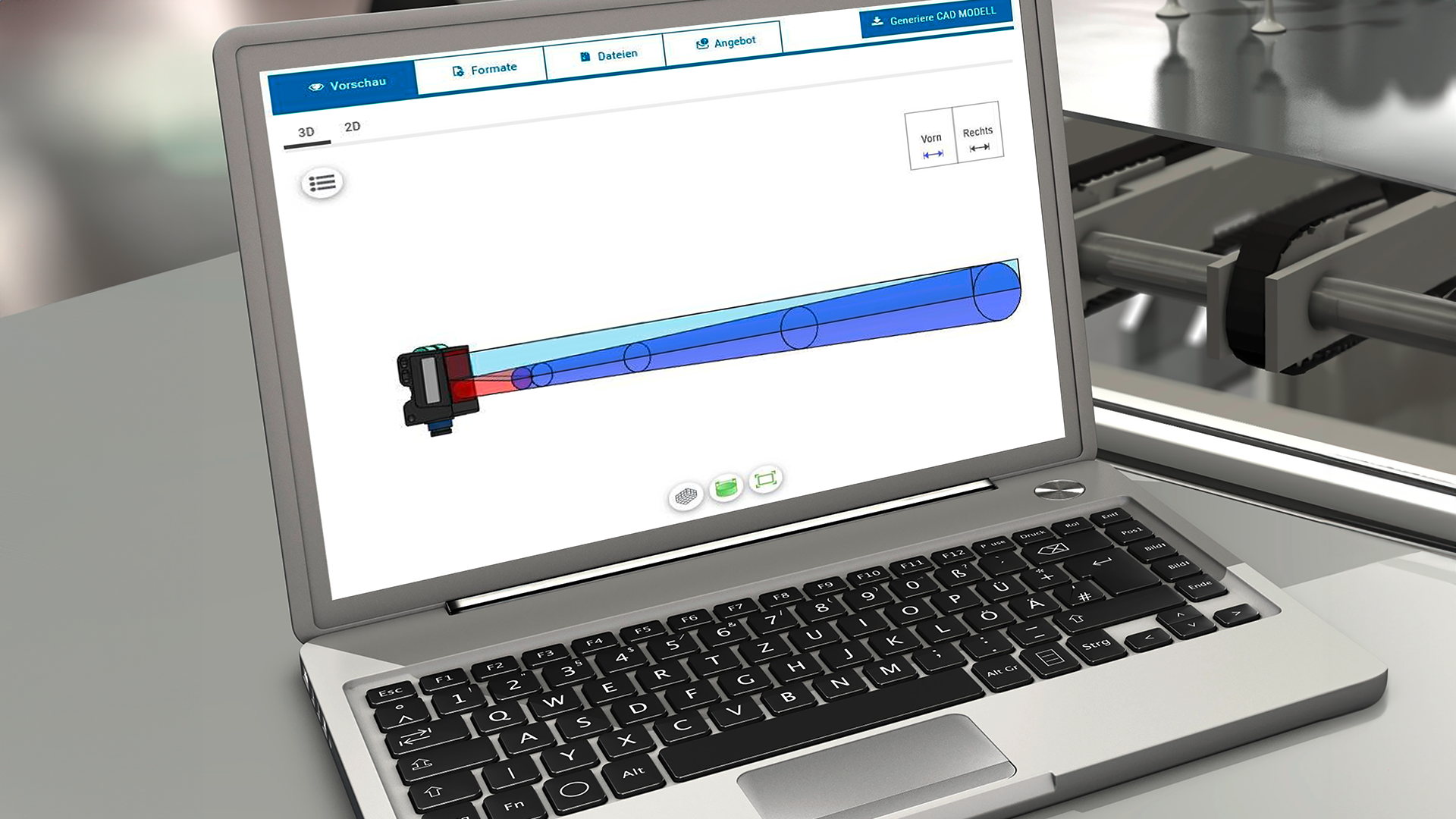

Let's look at a smart profile sensor, OXM200, as an example. This Baumer profile sensor is one of the most compact ones in its class, and in parallel particularly performant and lightweight. But how does the sensor integrate in a machine? How do blind region, receiver and detection range behave? To designers, these are the important questions. To cope with them, most users still follow the troublesome conventional procedure of collecting dimensions and coverage from data sheets for design-in via CAD. But this is time-consuming and prone to errors.

Baumer provides the digital CAD sensor twin

Smart functions to ease engineering work

Further to CAD sensor twins showing beam path or sonic lobe, there are even more free Baumer tools to support sensor engineering. This knowledge allows for optimal sensor installation and alignment. The Baumer Sensor Suite is a particularly popular software tool. Following to the motto "The smartest way to use IO-Link devices", this intuitive software will significantly simplify evaluation, parameterization and use of IO-Link sensors and actuators. Thanks to the Baumer Sensor Suite, the full potential of IO-Link sensors is quickly understood and exploited. On the screen, users see what the sensor is seeing. Such immediate visual feedback allows the engineer efficient, precise and quick parameterization of IO-Link devices.

Conclusion: Smart sensors are the backbone for efficient and robust automation, but can only develop their full potential when optimally installed and adjusted. With intelligent, free tools such as digital CAD sensor twins and the Baumer Sensor Suite software, Baumer helps users to quickly identify and easily exploit the numerous optimization possibilities offered by smart sensors.

Would you like to find out more about IO-Link? Then take a look here.