Product portfolio

Highlights

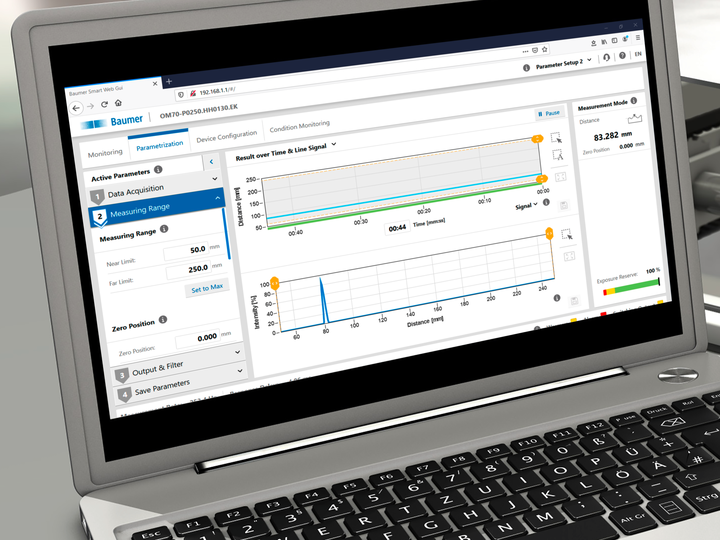

OM70 high-performance laser distance sensors offer an easy solution even for demanding measurement applications. The sensor can be quickly and optimally adjusted to the measurement task via the integrated web interface. The latest interfaces additionally ensure very easy integration.

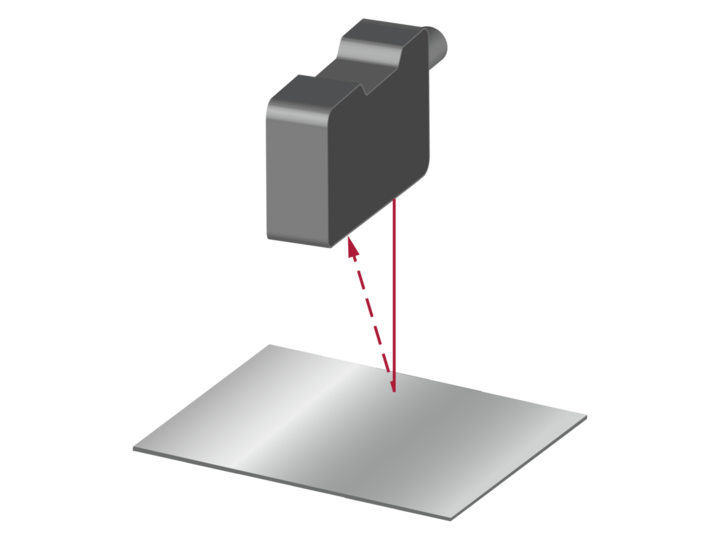

Reliable and precise –best-in-class measurement performance

Leading in usability – intuitive adjustment to the measuring application

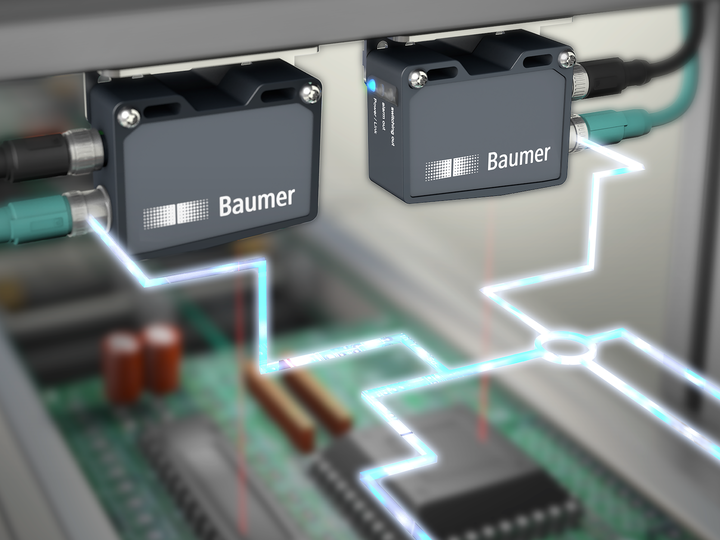

Connected – efficient integration with standardized interfaces

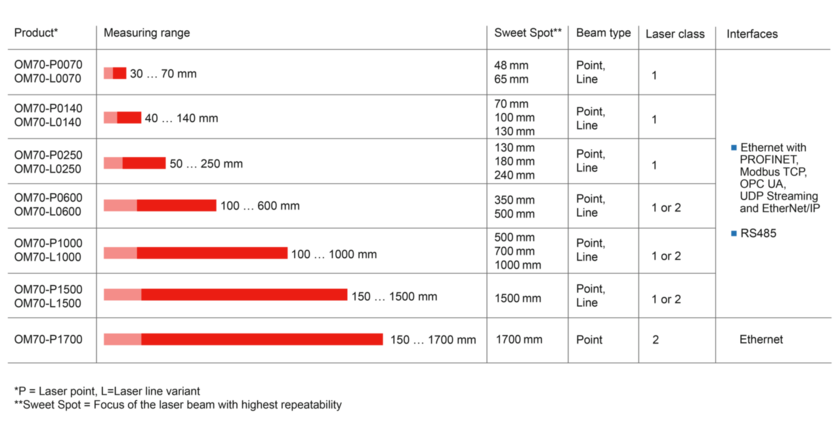

Selection guide

Always the optimum solution for your application

Find the right solution in only 5 steps:

1) Define the measuring range

In order to achieve the highest precision, the measuring range should be kept as small as possible.

2) Select the sweet spot

For particularly reliable measuring results, measurement should be done in the sweet spot (focus) of the laser.

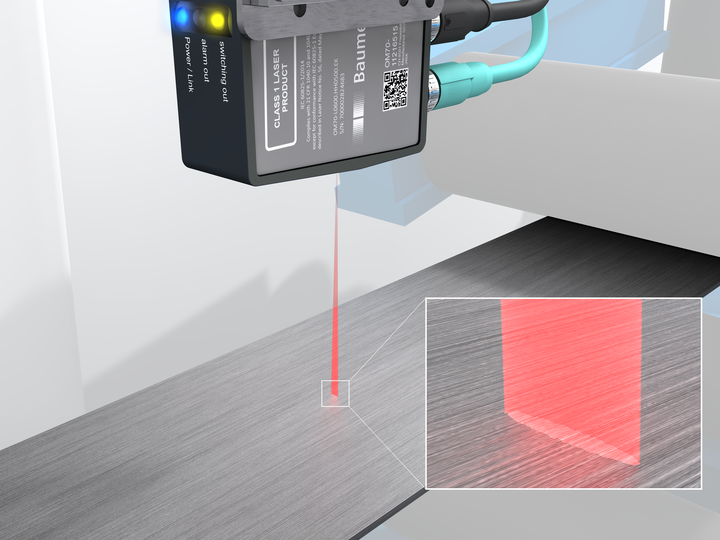

3) Define the beam shape

To increase the stability of the measured value, it is recommended to use a line beam shape. A point sensor is advantageous for measuring the smallest objects and jumps.

4) Select the laser class

A fast measurement on dark objects requires laser class 2; in all other cases laser class 1 is sufficient.

5) Define the interface

Here you have the choice between two variants: an Ethernet TCP/IP interface with a web interface or a serial interface with a display. Both versions provide an analog output.

Applications

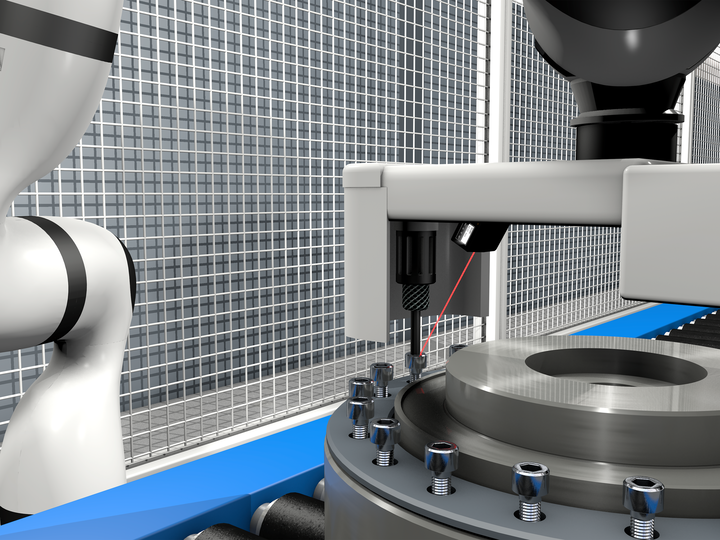

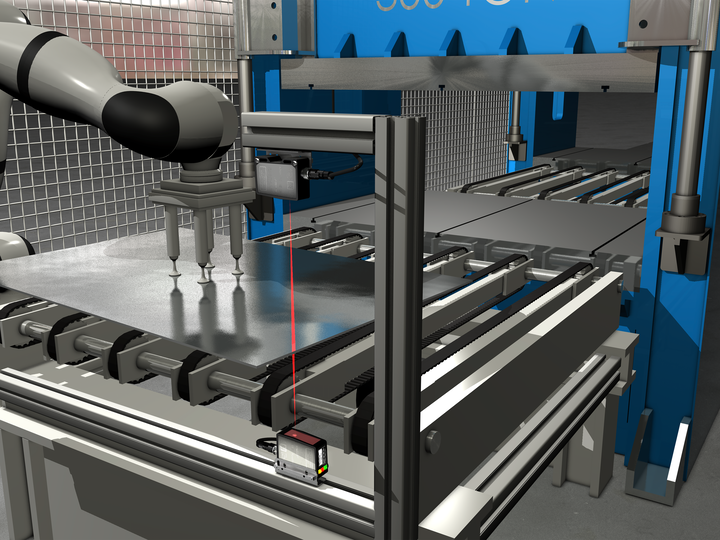

Exact robot positioning in production

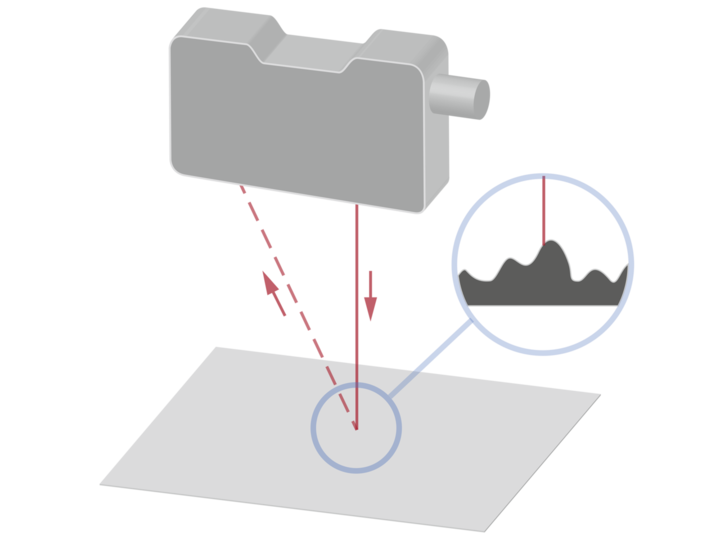

Thickness measurement of brushed metal

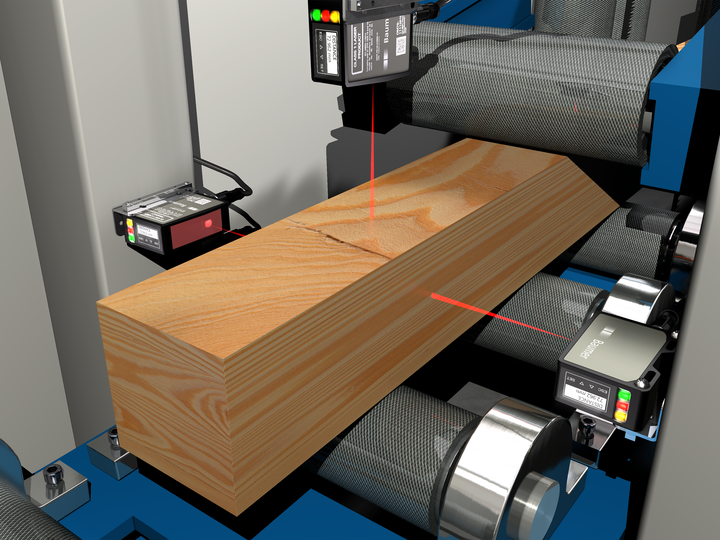

Dimensional control of wooden beams

Technology

Standardization

High reproducibility on miniature objects

Reliability even on optically demanding materials

Tutorial | Connected sensors

Tutorial | Intuitive web interface

Downloads

Brochures / Catalogs

-

Brochure – OM70 – Reliable, connected and leading in usability

Technical and Application Reports / White Paper

-

Application Report – Guarantee traceability through faultless laser marking

-

Technical Report – 5 steps to find the right laser distance sensor

-

Technical Report – Undeterred precision – OM70 with focus ranges

-

Technical Report – Laser distance measurement for all surfaces