Product portfolio

Technological highlights

FEX image processor

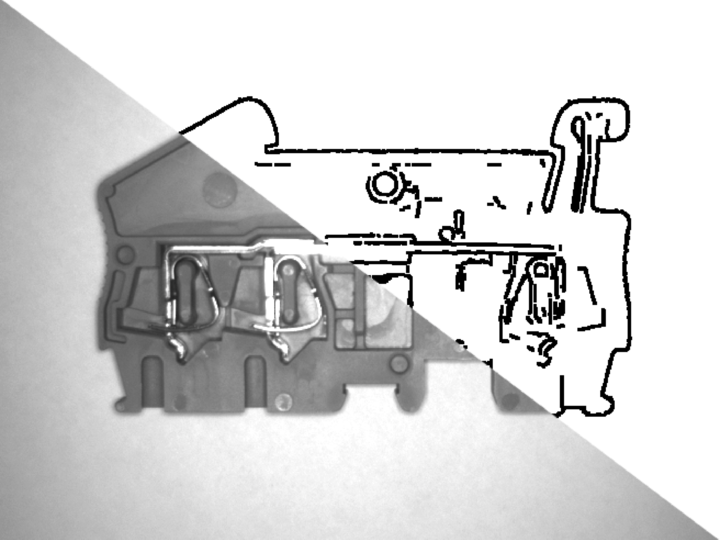

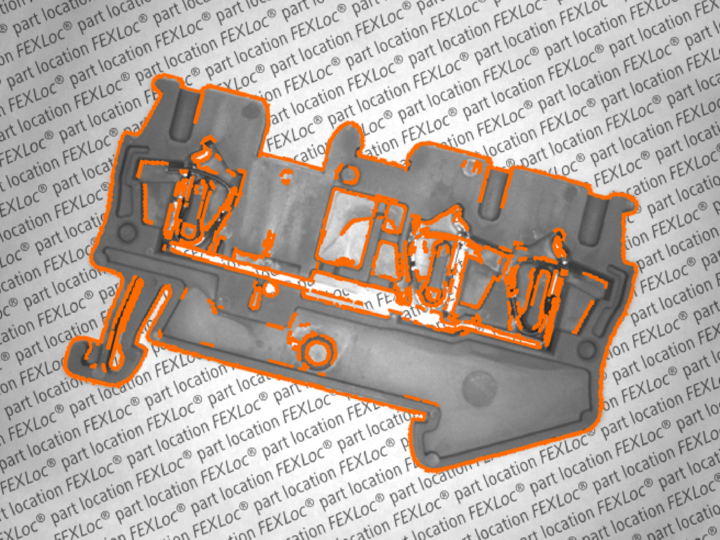

FEXLoc part location

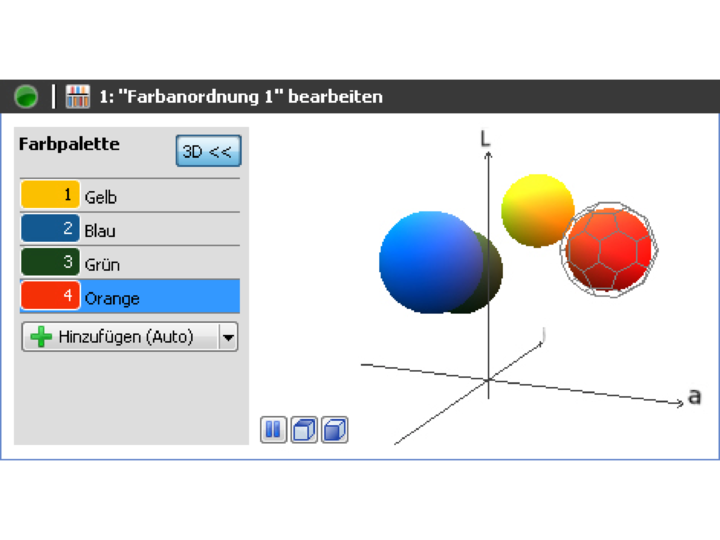

ColorFEX 3D color assistant

VeriFlash flash controller

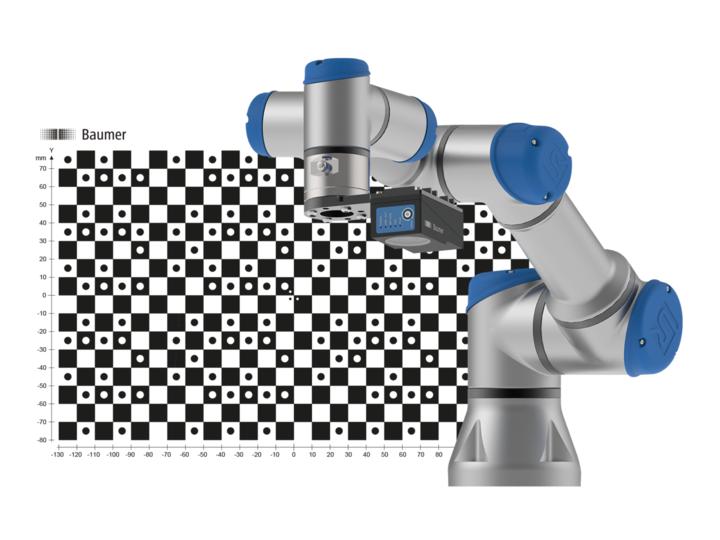

VeriSens SmartGrid – the intelligent calibration target

Distortion and shading correction

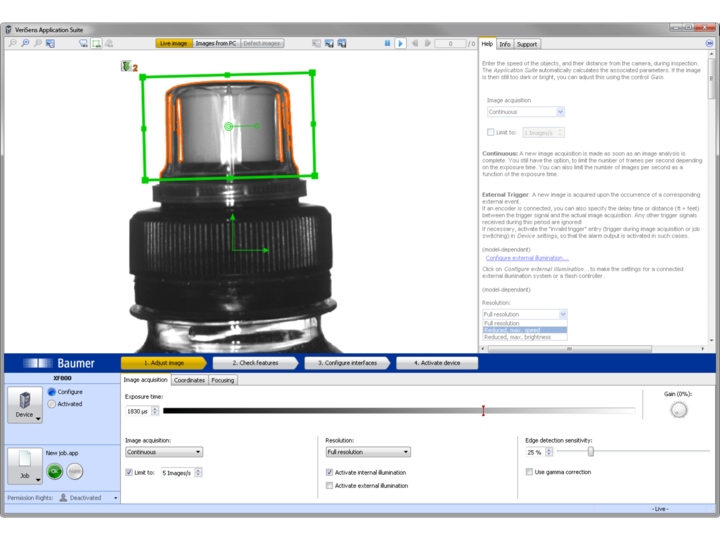

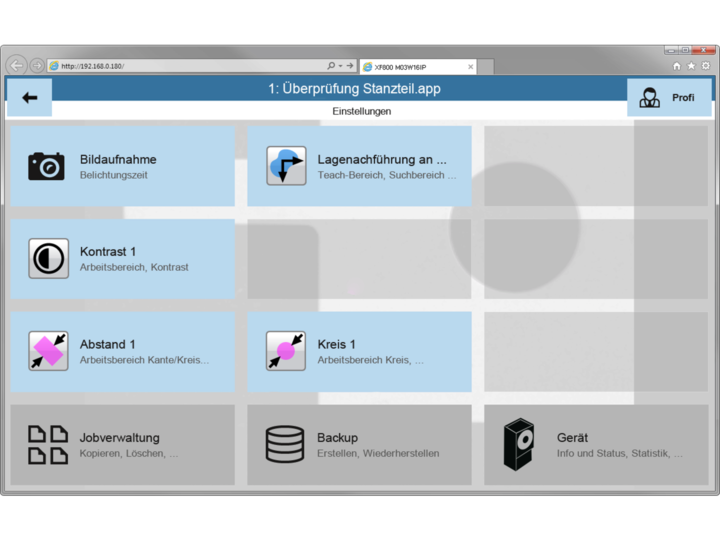

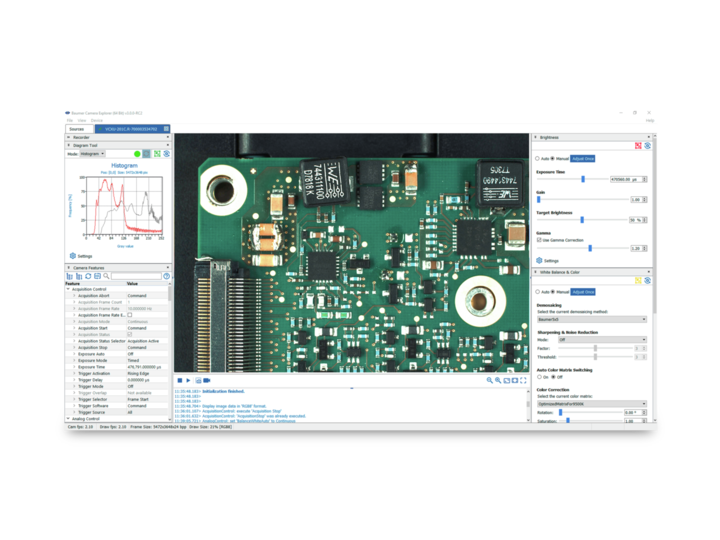

VeriSens web interface

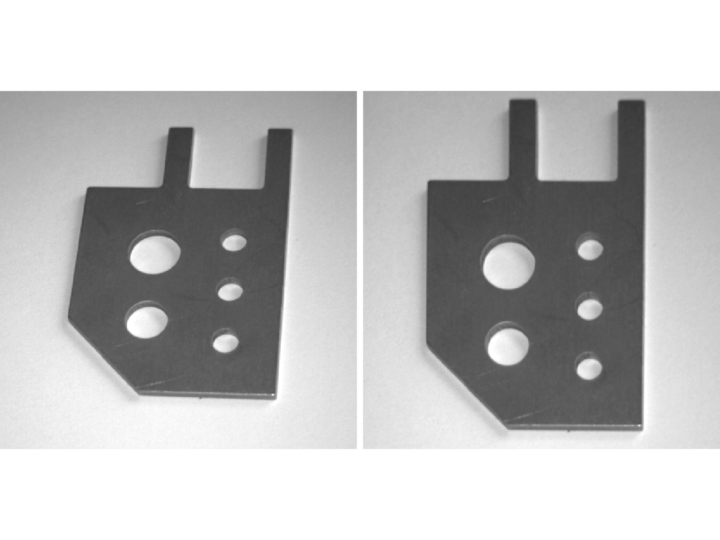

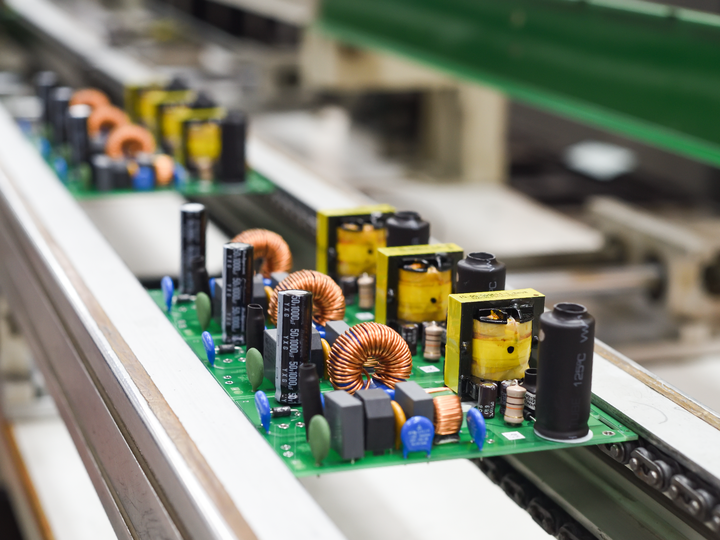

Image-based quality control

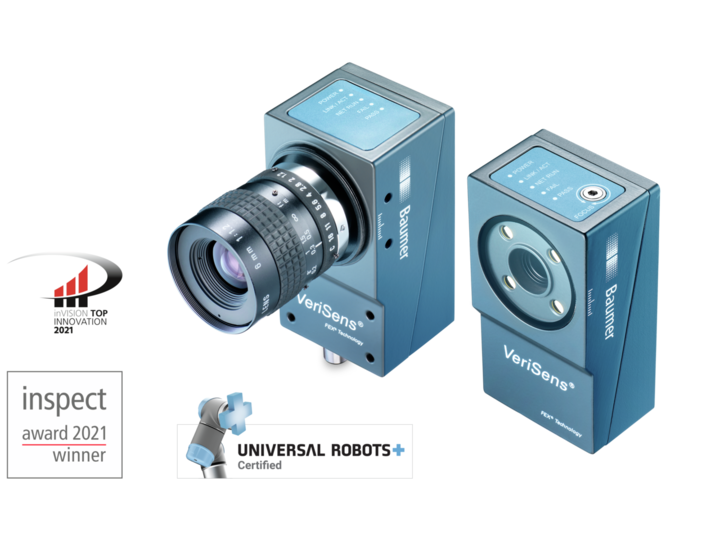

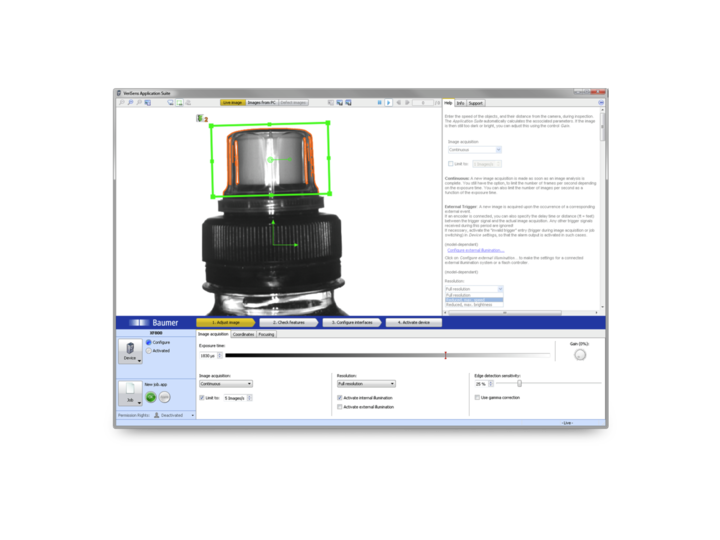

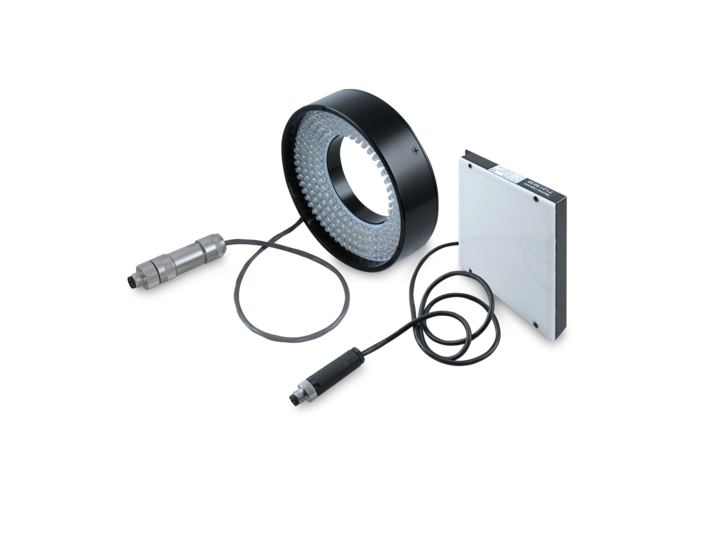

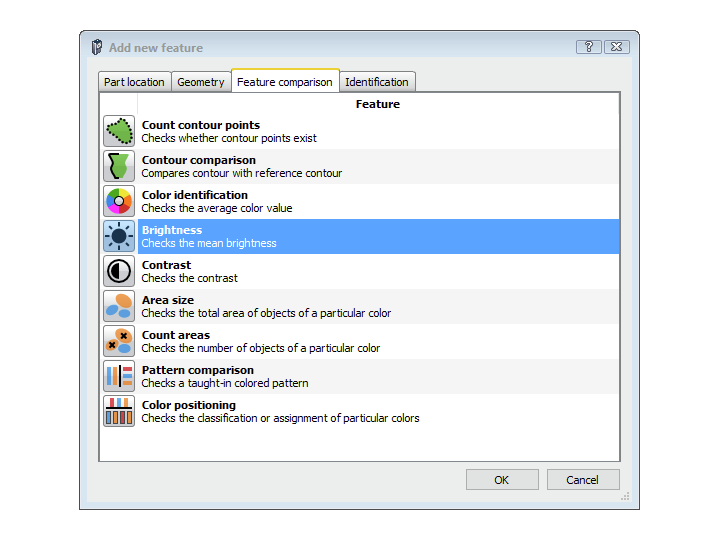

VeriSens vision sensors offer a complete image processing system in the shape of a sensor. Their compact industry-suited housing integrates an image sensor, illumination or illumination connection, lenses or interchangeable lens connection, software, as well as Ethernet and digital interfaces. They can therefore be used as inline solutions to check various features of products for early recognition and ejection of faulty parts. They offer 23 different feature checks. Following a one-time configuration on the PC with the VeriSens Application Suite, the vision sensors reliably perform their inspection tasks around the clock.

Which applications benefit from vision sensors?

Nowadays, practically everyone wants to benefit from the flexibility and versatility of image-based product inspections. However, in cases where PC-based image processing programs are too complex and expensive and the performance of optical sensors is too weak, vision sensors offer the ideal solution.

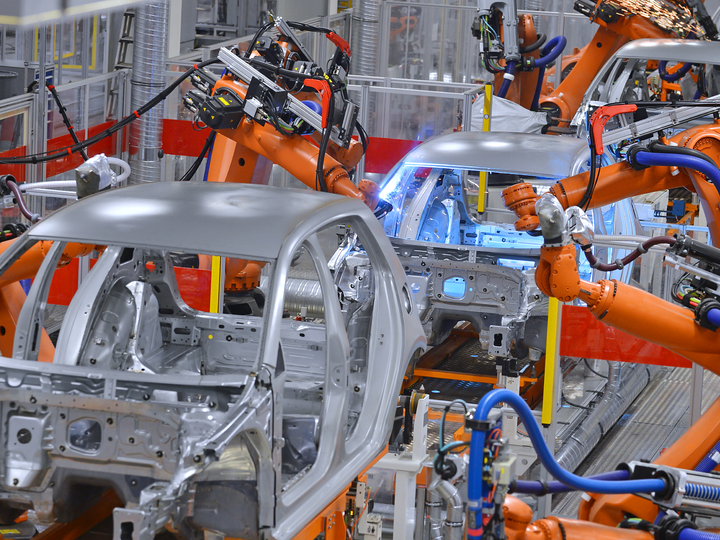

They operate particularly efficiently in applications in which several characteristics must be tested simultaneously or in which the position of the inspected objects is constantly changing. VeriSens vision sensors are also the ideal components when different batches are tested on a production line and the acquired data is to be forwarded for evaluation. Thanks to PROFINET and Ethernet/IP, time-critical processes can also be easily and affordably implemented via Industrial Ethernet.

Your benefits

- The solution for diverse inspection tasks

- Up to 23 high-performance feature checks

- Up to 32 feature checks combinable per job

- Up to 255 jobs can be stored on the vision sensor

- Reliable contour-based image processing in real time

- Patented FEX image processor

- Exact image evaluation and dimensional checks even if the vision sensors are mounted at an angle

- Real-time correction of distortion, shading, and perspective bias

- The fully integrated flash controller simplifies the system design, lowers costs, and saves integration time

- VeriFlash flash controller

- Set up color inspections fast and intuitively

- Intelligent 3D color assistant ColorFEX

- Reliable 360° part recognition without mechanical part alignment

- FEXLoc part location

- Real-time communication

- PROFINET and Ethernet/IP

- Secure communication and encrypted connection

- SFTP and HTTPS

- Store defect images and evaluate them at any time

- FTP or SFTP client

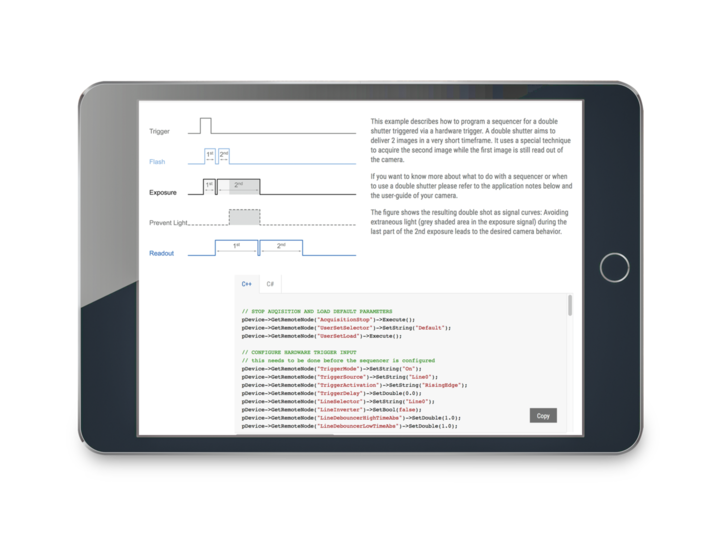

- Easy and fast configuration within minutes without programming languages

- VeriSens Application Suite with configurable web interface

Applications

Food & beverage industry

Food production

Packaging

Automotive

Electronics

Installation/handling

Downloads

Brochures / Catalogs

-

Brochure – VeriSens vision sensors: Image-based quality control – easy and intuitive

Technical and Application Reports / White Paper

-

White Paper – Color inspection made easy

-

Application Report – Image-based quality inspection at pressure gauges

-

Application Report – Monitoring of the loading and unloading process during freeze drying

-

Technical Report – Easy control of collaborating robots with vision sensors

-

Technical Report – Precise image analysis thanks to distortion and shading correction

-

Technical Report – Vision sensors: Decisive cameras in compact housing

-

Technical Report – How do vision sensors work?

-

Technical Report – Vision sensors in washdown design with IP 69K rating

-

Technical Report – VeriSens with ColorFEX: Multi-colored is my new favorite color

-

Technical Report – What actually is a vision sensor?

-

Technical Report – Next generation web interface for VeriSens vision sensors

-

Technical Report – Vision sensor software with visible user orientation

-

Technical Report – Flash controllers and vision sensors: Bringing together two worlds

-

Technical Report – Monitoring of Printed Product Information (OCR vs. OCV)

-

Technical Report – Industrial image processing components for the optimization of the solar modules manufacturing